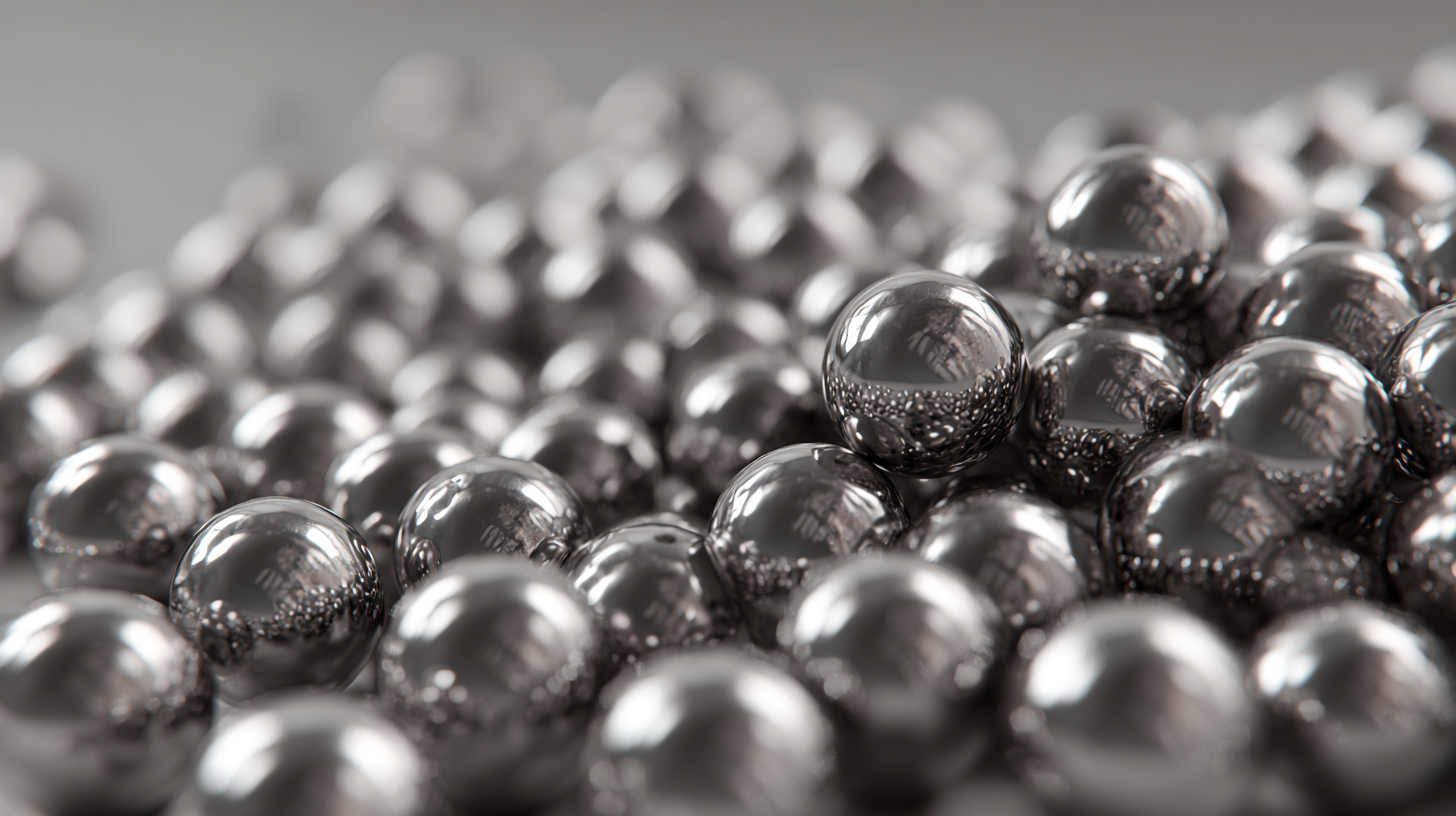

As the industrial landscape continues to evolve, the demand for high-performance materials is at an all-time high. Among these materials, stainless steel balls are gaining traction across various applications due to their durability, corrosion resistance, and enhanced performance. According to a recent market analysis by Grand View Research, the global stainless steel balls market size is anticipated to reach USD 3 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.4%. This growth is driven by advancements in manufacturing techniques and an increased focus on sustainability, making stainless steel balls an essential component in modern industrial processes.

Industry expert Dr. Emily Carter, a leading materials scientist at the International Society of Ball Bearing Engineers, emphasizes the significance of stainless steel balls in advancing industrial applications. She states, "The innovative properties of stainless steel balls not only improve efficiency but also contribute to a more sustainable production cycle." These trends are reshaping the landscape of industries ranging from automotive to aerospace, where precision and reliability are paramount.

In light of these developments, this article will delve into the top five trends transforming the stainless steel balls industry by 2025. By exploring these trends, we aim to provide insights into how businesses can leverage the advantages of stainless steel balls to optimize their operations and stay competitive in a rapidly changing market.

The stainless steel ball manufacturing industry is undergoing significant transformations driven by innovative materials and advanced manufacturing techniques. According to a report by MarketsandMarkets, the global market for stainless steel balls is projected to reach $4.1 billion by 2025, growing at a CAGR of 5.4%. This growth is fueled by increased demand in various sectors such as automotive, aerospace, and consumer goods, where precision and durability are critical.

One noteworthy trend is the development of high-performance stainless steel alloys that enhance corrosion resistance and reduce wear. For instance, manufacturers are increasingly utilizing martensitic stainless steels, which provide superior hardness and strength, making them ideal for high-stress applications. Additionally, advancements in surface treatment technologies, such as passivation and electropolishing, have significantly improved the surface finish and longevity of stainless steel balls. A recent study highlighted that these innovations could extend service life by up to 30%, providing companies with cost savings and enhanced operational efficiency.

The integration of additive manufacturing in stainless steel ball production is another game-changer, allowing for the creation of complex geometries and customized designs that were previously difficult to achieve. According to the ASTM International, additive manufacturing could reduce material waste by up to 70% compared to traditional methods. This capability not only streamlines manufacturing processes but also supports the growing trend of customization in industrial applications, providing a competitive edge in the marketplace.

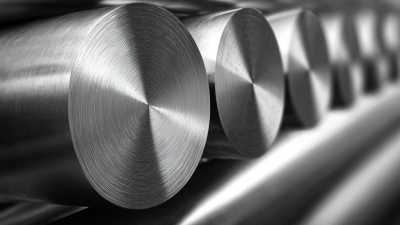

Advancements in surface treatment techniques are paving the way for enhanced performance in industrial applications, particularly with stainless steel balls. Recent innovations, such as specialized coating methods and surface engineering, are optimizing the functionality of these crucial components. For example, a breakthrough method for aluminum surfaces showcases how tailored surface topographies can revolutionize energy efficiency and anti-icing technologies. This approach could likely be adapted to improve the corrosion resistance and overall lifespan of stainless steel balls.

Advancements in surface treatment techniques are paving the way for enhanced performance in industrial applications, particularly with stainless steel balls. Recent innovations, such as specialized coating methods and surface engineering, are optimizing the functionality of these crucial components. For example, a breakthrough method for aluminum surfaces showcases how tailored surface topographies can revolutionize energy efficiency and anti-icing technologies. This approach could likely be adapted to improve the corrosion resistance and overall lifespan of stainless steel balls.

Another promising development is the application of spray-coating techniques, which offer precise control over the morphology of membrane materials. This technology is not only applicable in membranes but could also significantly enhance the wear resistance of stainless steel balls, ensuring greater durability in demanding industrial environments.

Tip: When considering upgrades to stainless steel components, investigate surface modification techniques that address specific performance challenges such as wear and corrosion. Balancing cost with the longevity provided by advanced treatments can lead to substantial savings in maintenance and replacement.

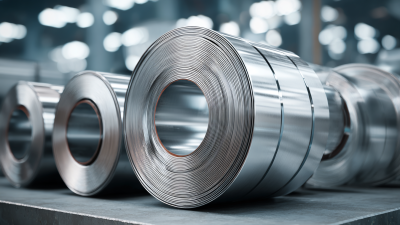

The stainless steel ball industry is increasingly embracing sustainability practices to address environmental concerns and enhance production efficiency. Manufacturers are implementing advanced recycling methods to minimize waste during the production process. By reusing scrap metal and optimizing raw material usage, companies can significantly reduce their carbon footprint while maintaining high-quality standards in their products. This move not only supports resource conservation but also aligns with growing consumer demand for sustainable manufacturing practices.

In addition to recycling, many producers are investing in energy-efficient technologies that minimize energy consumption and reduce greenhouse gas emissions. Innovations such as induction heating and automated processes help streamline manufacturing while ensuring lower energy usage. Furthermore, the shift towards utilizing renewable energy sources is becoming more prevalent, allowing companies to power their operations with cleaner energy, thus contributing to a more sustainable industrial environment. As these trends gain momentum, the stainless steel ball industry is poised to play a crucial role in promoting environmental responsibility within industrial applications.

The integration of smart technology, particularly the Internet of Things (IoT), is significantly reshaping industrial applications, including the production and use of stainless steel balls. According to a report by MarketsandMarkets, the global IoT in manufacturing market size is projected to reach $195 billion by 2025, growing at a CAGR of 25.7%. This rapid growth underscores the increasing reliance on IoT devices to enhance operational efficiency, reduce downtime, and streamline production processes.

In the context of stainless steel balls, IoT-enabled solutions facilitate real-time monitoring and predictive maintenance. Manufacturers can leverage sensors to gather data on wear and performance, allowing for timely interventions before failures occur. A study by Deloitte highlights that implementing IoT technologies can lead to a 30% reduction in maintenance costs and a significant improvement in productivity. As industries become more interconnected, the ability to analyze data generated from these stainless steel components will enable companies to optimize their supply chains and improve product quality, further solidifying the trend toward smart manufacturing.

The stainless steel balls market is experiencing significant transformations driven by evolving consumer demands. In various industrial applications, the need for higher quality and performance is becoming paramount. This shift is particularly evident as industries strive to enhance product durability and reliability. Manufacturers are adapting their production processes, focusing on precision engineering and innovative techniques to meet these rising expectations.

Consumer preferences are also steering the market towards sustainable and eco-friendly options. As industries become more conscious of their environmental impact, there is a growing demand for materials and processes that align with sustainability goals. This trend is likely to propel advancements in stainless steel ball production methodologies, ensuring that the products not only meet performance standards but also contribute positively to environmental outcomes. The interplay between consumer demands and production innovations is set to shape the future landscape of industrial applications of stainless steel balls significantly.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.