In the world of mechanical engineering, plastic ball bearings have gained significant attention. These components offer distinct advantages over traditional metal counterparts. They are lightweight, resistant to corrosion, and can withstand diverse environmental conditions. According to a report by Market Research Future, the plastic bearing market is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026.

However, while plastic ball bearings provide enhanced performance and reliability, not all products are created equal. Users may sometimes overlook quality, focusing instead on cost. This can lead to premature failure and unexpected maintenance. Research indicates that 30% of machinery downtime is attributed to bearing failure, emphasizing the need for careful selection of materials and manufacturers.

The right plastic ball bearing can significantly reduce friction and improve efficiency in various applications. Industries such as automotive and aerospace particularly benefit from these innovations. Yet, ensuring optimal performance requires a commitment to thorough product testing and ongoing evaluation. Understanding the trade-offs in material properties remains crucial for achieving desired results.

Plastic ball bearings are critical components in various applications. They serve industries like automotive, aerospace, and manufacturing. These bearings are preferred for their lightweight and corrosion-resistant properties. Studies indicate that using plastic over metal can reduce weight by up to 50%. This reduction improves overall efficiency in machines, enhancing performance.

When selecting plastic ball bearings, consider their operating environment. High temperatures or exposure to chemicals can impact their performance. Properly assessing these conditions can prevent premature failure. Reports show that improper material selection contributes to 30% of bearing breakdowns.

Tips for selecting the right bearings include checking load ratings and lubrication needs. Ensure compatibility with the application to avoid issues. Regular maintenance can prolong lifespan. Inspect bearings frequently for wear signs. Remember, even high-quality bearings may fail if not used correctly.

| Model | Material | Load Capacity (N) | Max Speed (RPM) | Temperature Range (°C) | Applications |

|---|---|---|---|---|---|

| PBB1001 | Polyamide | 300 | 5000 | -40 to 100 | Robotics, Medical Devices |

| PBB1002 | Polyethylene | 250 | 4500 | -30 to 80 | Aerospace, Automotive |

| PBB1003 | PTFE | 400 | 6000 | -200 to 120 | Chemical Industry, Food Processing |

| PBB1004 | Acetal | 350 | 5200 | -20 to 90 | Textile Machines, Conveyor Systems |

| PBB1005 | Polycarbonate | 300 | 4800 | -40 to 100 | Electronics, Consumer Goods |

Plastic ball bearings have gained popularity for their smooth performance and reliability. Their key materials offer unique properties that make them suitable for various applications. For instance, nylon and acetal are commonly used due to their excellent strength-to-weight ratios and resistance to moisture. According to the American Society for Testing and Materials (ASTM), nylon exhibits a low coefficient of friction, which translates to enhanced efficiency in machinery.

Another critical property is chemical resistance. Polypropylene, for example, withstands harsh environments better than many metals. A study published by the International Journal of Engineering Research and Applications highlights that plastic bearings can endure corrosive substances. However, the material choice can affect performance. Some plastics may warp under high temperatures, leading to potential failures.

The capability to absorb shock and vibration is another key benefit. Plastic materials tend to dampen noise better than metallic counterparts. This characteristic helps in applications where quiet operation is essential. Yet, plastic ball bearings may have lower load-bearing capacities compared to metal ones. Users must carefully consider their specific needs when choosing materials. Understanding these properties allows engineers to make informed decisions for optimal performance.

Plastic ball bearings are becoming increasingly popular due to their unique performance characteristics. They offer lightweight solutions without compromising on strength. However, various factors can significantly affect their reliability. Environmental conditions like temperature and humidity play a crucial role. High temperatures can lead to deformation. Excess moisture might promote corrosion.

For optimal performance, consider the application environment before selecting bearings. Evaluate load capacity and speed requirements. Knowing these can prevent unexpected failures. Regular maintenance checks can surface hidden issues early.

Tips: Use lubrication suited for plastic. It helps reduce friction, enhancing longevity. Also, test bearings under actual conditions to gauge performance. Don’t overlook minor damages; they can escalate into bigger problems. Ensure proper alignment during installation. Misalignment can cause uneven wear, affecting performance negatively.

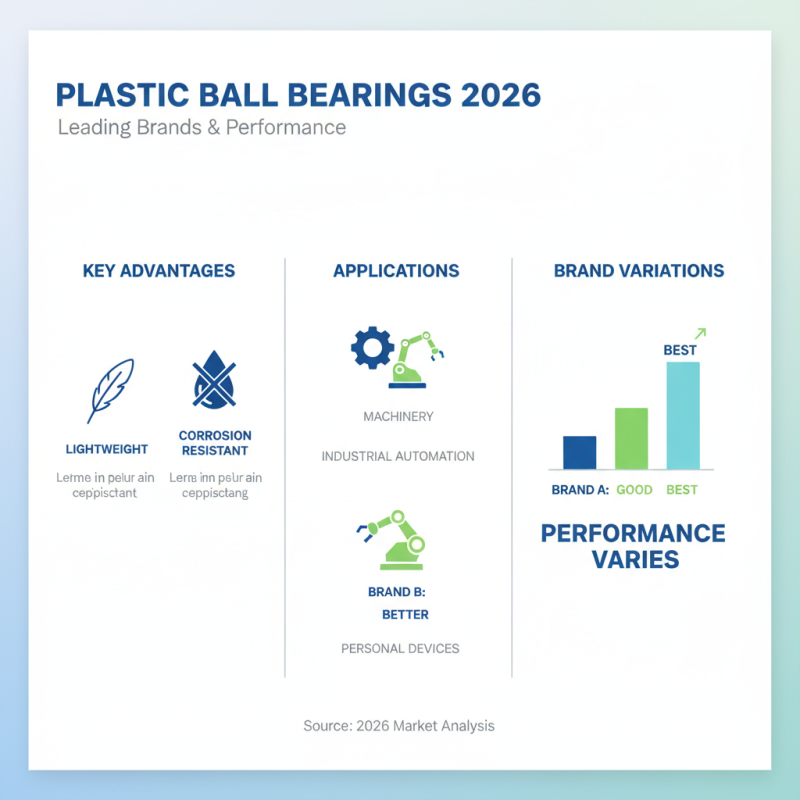

When exploring the best plastic ball bearings for 2026, it is crucial to examine various leading brands. These bearings play a significant role in countless applications, from machinery to personal devices. Their lightweight nature and corrosion resistance make them appealing. However, the performance can vary significantly between brands.

Some brands boast impressive load ratings and high-speed capabilities. Yet, durability is often a concern. Users may find that certain bearings wear out faster than expected. While many factors contribute to this, material quality stands out. There are instances where cheaper options compromise longevity. Maintenance can also be a hassle, with some requiring regular lubrication or adjustments. Testing these bearings under real-world conditions is necessary.

Price points can be misleading, too. A more expensive bearing does not always guarantee better performance. Users must consider their specific needs. Some may prioritize quiet operation over speed. Others may require temperature resistance. It often requires trial and error to identify the best fit. Pushing these bearings to their limits will reveal their true capabilities. In the end, making an informed decision is key.

The demand for plastic ball bearings is rising as industries seek lightweight and durable solutions. Recent studies show that the global plastic bearings market will grow by 4% annually until 2026. This growth highlights a shift towards innovative materials that offer high performance and reliability.

Future innovations in plastic ball bearings focus on advanced polymers. These materials can withstand higher loads and provide lower friction. Research indicates that bearings made from new composites can perform 30% better than traditional designs. However, developing these materials requires significant investment and time. Many manufacturers face challenges in achieving optimal performance while maintaining cost-effectiveness.

Sustainability is another key consideration in future innovations. Companies are exploring bio-based plastics that reduce environmental impact. Yet, these materials often struggle with durability and thermal stability. Finding the right balance between sustainability and performance remains a critical challenge in the industry. As technology advances, the journey of improving plastic ball bearings is ongoing and reflective of broader trends in material science.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.