In the world of mechanical engineering, 8mm ball bearings play a crucial role in various applications. These small yet powerful components are widely used in motors, machinery, and even consumer electronics. According to a report by the International Bearing Association, the demand for small bearings is projected to grow by 7% annually in the coming years. This underscores the importance of understanding their function and benefits.

Renowned bearing expert Dr. Anna Smith stated, "The efficiency of machinery heavily relies on the precision and reliability of 8mm ball bearings." Her insight highlights their significance in improving performance and reducing friction. These components are designed to endure heavy loads while maintaining smooth movement, making them essential for both industrial and commercial applications.

However, despite their robust design, users often overlook their maintenance. Neglect can lead to premature failure and inefficiencies. It is vital to consider factors such as lubrication and alignment. This awareness is key to maximizing the lifespan and effectiveness of 8mm ball bearings in various mechanical systems.

An 8mm ball bearing is a small, spherical component used to reduce friction. It consists of a smooth ball housed between two rings, known as races. The size indicates the diameter of the ball, which in this case is 8 millimeters. These bearings are crucial in various mechanical systems, allowing parts to move smoothly against one another.

In terms of specifications, the 8mm ball bearing typically features precision steel or ceramic materials. They can endure high speeds and heavy loads. Their simple design aids in easy installation and maintenance. You’ll find them in machines, bicycles, and even electronics. However, selecting the right kind can be tricky. Factors like load capacity and speed ratings must be considered. A wrong choice may lead to premature failure or inefficiency.

Users often overlook the importance of proper lubrication. Insufficient grease can lead to increased friction. This often results in overheating and potential damage. Ball bearings warrant regular inspections. Even minor wear can significantly impact performance.

| Dimension | Specification | Material | Applications |

|---|---|---|---|

| 8mm x 22mm x 7mm | Deep Groove Ball Bearing | Steel | Electric Motors, Gearboxes |

| 8mm x 22mm x 7mm | Shielded Ball Bearing | Stainless Steel | Bicycles, Skateboards |

| 8mm x 16mm x 5mm | Miniature Ball Bearing | Plastic | Robotics, Toys |

| 8mm x 24mm x 8mm | Sealed Ball Bearing | Chrome Steel | Automotive, Machine Tools |

The manufacturing process of 8mm ball bearings involves several critical steps. Initially, raw materials such as steel or ceramic are selected based on the desired properties. Steel is commonly used for its strength, while ceramics offer corrosion resistance. The choice significantly affects performance.

Once materials are chosen, they undergo a shaping process. This typically includes forging or machining. In forging, the material is heated and shaped under pressure. Machining, on the other hand, includes cutting and grinding to achieve precise dimensions. Each method has its trade-offs, impacting strength and surface finish.

After shaping, the ball bearings are hardened through heat treatment. This enhances their durability. The hardening process, albeit essential, can introduce inconsistencies. Visual inspection follows, ensuring quality. However, not all defects are immediately visible. Often, flaws can persist undetected until the bearing is in use. Finally, the bearings are lubricated and packaged. The entire process demands precision and attention. Each step reflects the careful balance of quality and efficiency, reminding us that even small components play a crucial role in larger systems.

8mm ball bearings play a pivotal role across various industries. Their compact size and robust design make them ideal for numerous applications. In automotive sectors, they are used in engines, transmissions, and wheel hubs. These bearings ensure smooth motion and reduce friction.

In the manufacturing world, 8mm ball bearings support conveyor systems and robotic arms. They enhance efficiency and precision in operations. For hobbyists, these bearings are essential in model building and small machinery. Their lightweight nature allows for easy assembly and manipulation.

Tips: Always ensure proper lubrication for optimal performance. Regularly check for signs of wear and tear. Sometimes, a minor oversight can lead to larger issues down the line. Keeping a close eye on these factors can extend the lifespan of the bearings significantly.

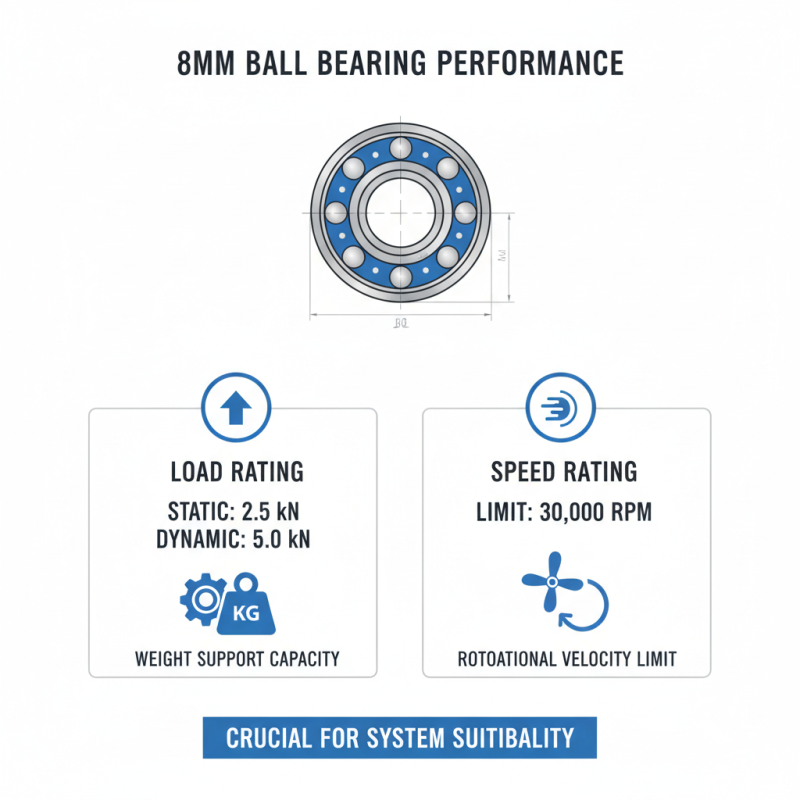

8mm ball bearings are essential components in various mechanical systems. Their performance characteristics play a vital role in determining their suitability for different applications. Key specifications include load ratings and speed ratings, which define how much weight they can support and how fast they can rotate without failing. Understanding these ratings is crucial.

Load ratings indicate the maximum load a bearing can handle when stationary or moving. An 8mm ball bearing typically supports a moderate load, making it suitable for applications like small motors and robotics. Speed ratings refer to the optimal rotational speed under which the bearing operates efficiently. Exceeding speed limits can lead to overheating and failure.

However, the design of an 8mm ball bearing may not suit every application. Factors like lubrication, environmental conditions, and mounting can affect performance. Improper installation can lead to uneven wear and premature failure. Users must reflect on these aspects to ensure the longevity and reliability of ball bearings in their projects.

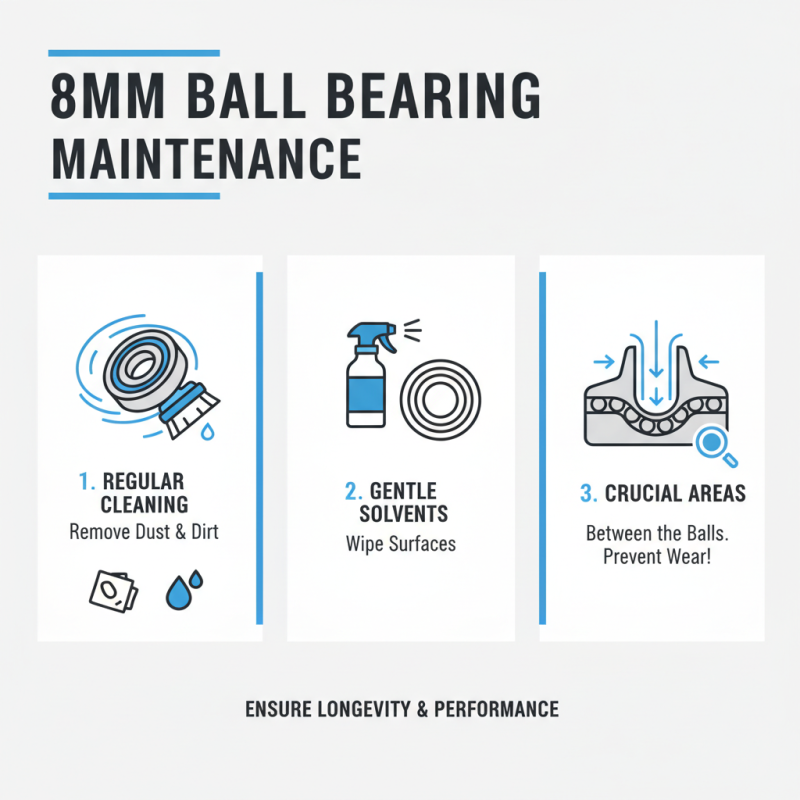

Maintaining 8mm ball bearings is crucial for ensuring their longevity and performance. Regular cleaning is essential. Dust and dirt can accumulate, affecting smooth operation. Use a soft cloth and gentle solvents to wipe the surfaces. Pay attention to the areas between the balls; contamination can cause wear. It’s easy to overlook these spots, but neglect can lead to premature failure.

Lubrication is another key factor. Apply appropriate grease or oil to keep the bearings running smoothly. But too much lubricant can attract dirt. Finding the right balance is important. Consider the environment where the bearings operate. High humidity or dust can affect the choice of lubricant.

Frequent inspections can help catch issues early. Look for signs of rust or wear. Addressing problems promptly can prevent larger failures down the line. Sometimes, we forget to check, thinking everything is fine. But a brief inspection can save time and cost later. Keeping a maintenance schedule can help remind you to check your bearings regularly.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.