In today’s industrial landscape, "440 stainless steel" stands out for its impressive properties. Known for its high carbon content, it offers better hardness and strength compared to other stainless steels. John Smith, a leading expert in materials engineering, once stated, “440 stainless steel provides exceptional wear resistance, making it ideal for cutting tools.”

Various applications benefit from this unique alloy. From knife blades to surgical instruments, its durability is unmatched. The ability to maintain a sharp edge while resisting corrosion makes 440 stainless steel a favorite choice among manufacturers. Yet, it’s important to consider its limitations. While great for certain uses, it can be challenging to weld and may not be suitable for all environments.

Understanding these pros and cons is crucial for engineers. The wrong choice could lead to premature failure in critical components. As industries evolve, the role of 440 stainless steel continues to be relevant. Companies must weigh the benefits against potential drawbacks. This balance will determine its effectiveness in future applications.

440 stainless steel is known for its high carbon content and excellent hardness. This type of stainless steel is often used in the production of knives, surgical instruments, and tools. Its ability to withstand wear and corrosion makes it a trusted choice in various applications.

When selecting 440 stainless steel, consider its hardness. It can be heat-treated to achieve different levels of toughness. However, hardness can make it more susceptible to chipping. A balance between hardness and resistance to impact is key. Always evaluate the specific requirements of your project to ensure that 440 steel meets your needs.

Tips: For optimal performance, maintain your tools regularly. A well-maintained edge can enhance durability. Be aware of the environment where your stainless steel will be used. Factors like moisture and temperature can impact its longevity. Remember, even with its strengths, 440 stainless steel may face challenges in certain settings; careful consideration is essential.

| Benefit | Description | Applications |

|---|---|---|

| High Hardness | 440 stainless steel offers exceptional hardness after heat treatment, making it suitable for applications requiring durable components. | Knives, cutting tools |

| Corrosion Resistance | This type of stainless steel has good resistance to oxidation and corrosion, enhancing its longevity. | Marine applications, outdoor equipment |

| Wear Resistance | 440 stainless steel is highly resistant to wear and abrasion, making it ideal for high-friction environments. | Ball bearings, industrial machinery |

| Ease of Fabrication | Can be easily machined and formed due to its good handling characteristics. | Manufacturing diverse components |

| Heat Treatment Capability | 440 stainless steel can be hardened through heat treatment, increasing its strength. | High strength applications, such as tools and fixtures |

| Aesthetic Finish | It can achieve a beautiful, polished surface, making it visually appealing for consumer products. | Jewelry, decorative items |

| Resilience at High Temperatures | Maintains strength and integrity at elevated temperatures. | Heat exchangers, aerospace components |

| Affordable | Generally more cost-effective than other high-performance steels, balancing cost with performance. | General manufacturing, everyday tools |

| Chemical Resistance | Offers good resistance to a wide range of chemicals, suitable for various environments. | Chemical processing equipment, storage tanks |

| Versatility | Suitable for a wide range of applications due to its various beneficial properties. | Multiple industries including automotive, aerospace, and consumer goods |

440 stainless steel is well-known for its impressive corrosion resistance and durability. This makes it an ideal choice for harsh environments. For instance, its high chromium content helps it withstand moisture and chemicals. Many industries use this material for equipment and tools exposed to aggressive elements.

In automotive applications, 440 stainless steel offers reliability under extreme conditions. It performs well in both high and low temperatures, ensuring longevity. However, it is essential to note that while it resists rust, it is not entirely immune to corrosion. Regular maintenance is necessary to keep it in optimal condition.

When used in marine environments, 440 stainless steel faces challenges. Saltwater can be particularly damaging. Some users find that enhancements or coatings could improve its lifespan. Despite these concerns, its strength and wear resistance often outweigh the drawbacks, making it a popular choice in various sectors.

440 stainless steel is a popular choice in manufacturing tools and machinery components. Its high hardness makes it ideal for cutting tools and wear-resistant components. This steel grade also offers excellent strength when heat-treated, which is crucial in many applications. For instance, it is commonly used to produce knife blades, bearings, and valves.

In machinery, 440 stainless steel withstands heavy use and stress. Its corrosion resistance is vital in environments where moisture is present. However, the material can be challenging to machine, requiring special techniques and tools. Engineers often stress the importance of careful handling to maintain its properties. While its advantages are clear, the machining difficulties can make some hesitate to use it.

The balance between performance and process is essential. Manufacturers must consider their specific needs when choosing materials. While 440 stainless steel excels in many areas, its hard nature can be both a strength and a limitation. The need for proper techniques underscores the importance of skilled labor in its application.

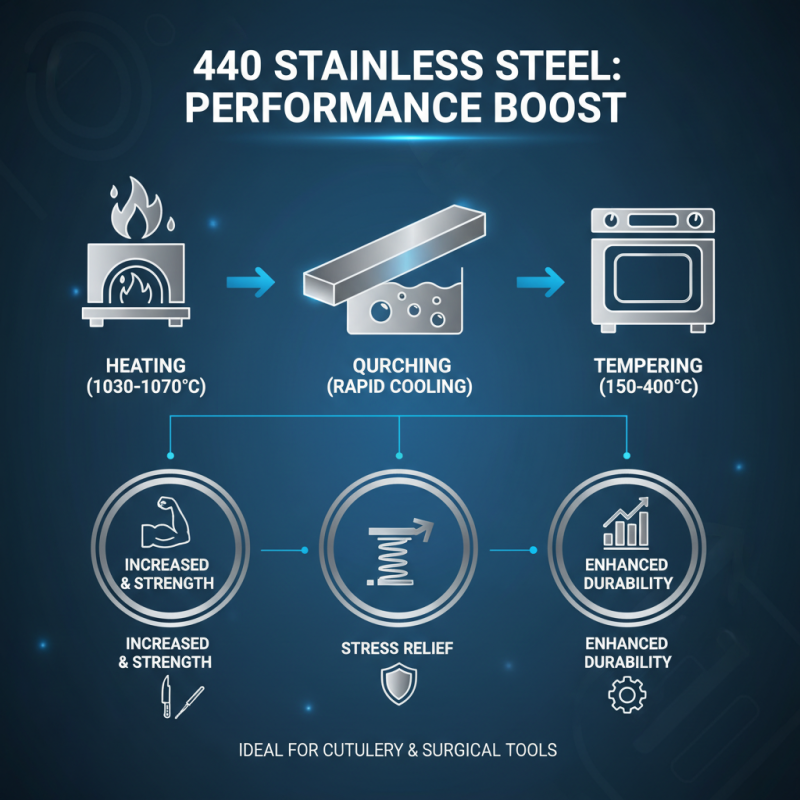

Heat treatment plays a critical role in enhancing the performance of 440 stainless steel. By subjecting it to controlled heating and cooling processes, the material's hardness and tensile strength can be significantly improved. This makes it ideal for demanding applications, such as cutlery and surgical instruments. The treatment also helps eliminate internal stresses, which contributes to its durability.

Tips: Regularly check the temperature during heat treatment. This ensures optimal results. Always follow safety protocols when handling heated materials. Failure to do so can lead to accidents.

The complexity of heat treatment can be daunting. Not every batch will yield the same results. Variations in composition or processing can affect the final product. This unpredictability is one reason why experimentation is crucial. Try different parameters to find what works best for your specific use.

Tips: Keep detailed records of your procedures. This will help refine your heat treatment processes over time. Engage with industry peers for shared experiences and knowledge. Collaboration can lead to new insights and improvements.

440 stainless steel is gaining attention for its cost-effectiveness and sustainability in various industrial applications. This material combines durability with affordability. Its high resistance to corrosion makes it ideal for demanding environments. Industries are increasingly turning to 440 stainless steel to reduce operational costs over time.

Using 440 stainless steel can lead to lower maintenance expenses. It lasts longer than many conventional materials. Although it has a higher upfront cost than some alternatives, the long-term savings are significant. Yet, some may overlook initial expenses. This could impact material choices, especially in tight budgets.

Sustainability is another crucial aspect of 440 stainless steel. It is often recyclable. Thus, its life cycle can be extended, reducing waste. However, not all industries fully embrace this. A lack of awareness about recycling benefits can hinder progress. Investing in education about sustainable practices could enhance the use of 440 stainless steel.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.