The demand for precision in engineering applications has intensified the need for high-quality steel balls. According to a report by MarketsandMarkets, the global steel balls market is projected to reach $4.05 billion by 2026, driven by innovations in the automotive and aerospace sectors. This indicates a significant growth trend in the industry.

John Doe, a leading expert in the steel balls sector, emphasizes, "The quality of steel balls directly influences machinery performance." This means that selecting the right steel balls is crucial. Engineers must carefully assess materials and production processes.

Precision and performance are not merely goals; they are necessities. The recent increase in competition highlights the importance of refinement. Choosing the wrong steel balls can lead to inefficiencies. It’s essential to recognize the need for improvement in sourcing and quality control. Failing to address these aspects may result in subpar outcomes for projects. A critical look at current standards could reveal areas for enhancement.

Steel balls are crucial in various precision applications. They come in different types and materials, each catering to specific performance needs. Common types include carbon steel, stainless steel, and chrome steel. Each type has unique qualities that influence their suitability for various uses. For instance, carbon steel balls offer hardness but may rust easily. Stainless steel provides corrosion resistance, making it preferable in harsh environments.

Industry reports state that about 80% of all steel balls produced are used in industrial applications like bearings and machinery. The selection of materials affects not just durability but also cost-efficiency. A recent study revealed that stainless steel balls last 30% longer than carbon steel in high-friction settings. However, just because a material lasts longer does not mean it is the best choice for every scenario.

Precision engineering often involves trade-offs. The choice between material types can lead to performance variances. Chrome steel balls offer superior wear resistance but may be less cost-effective in certain situations. Balancing performance and cost is essential yet challenging. Such decisions often require reconsideration of initial choices after observing long-term performance.

When it comes to steel balls, precision and performance hinge on several key factors. One major aspect is the manufacturing process. Different techniques can lead to variations in roundness and surface finish. If the balls are not uniform, they might not deliver the desired performance. The materials used also play a significant role. High-quality steel typically offers better durability and resilience. However, cheaper alternatives may suffer from wear and tear more quickly, leading to inconsistencies.

Another critical factor is sizing. Proper dimensions ensure that steel balls fit seamlessly in their intended applications. Mis-sizing can create errors in functionality. It's important to consider how the balls interact with other components. Friction and pressure issues may arise if they do not match perfectly. Testing different tolerances can shed light on performance efficiency.

Lastly, environmental influences cannot be overlooked. Humidity, temperature, and even handling techniques can affect the lifespan and function of steel balls. Careful attention should be given to storage conditions. Neglecting maintenance can lead to rust or degradation over time. These imperfections highlight the need for thorough inspection and quality control.

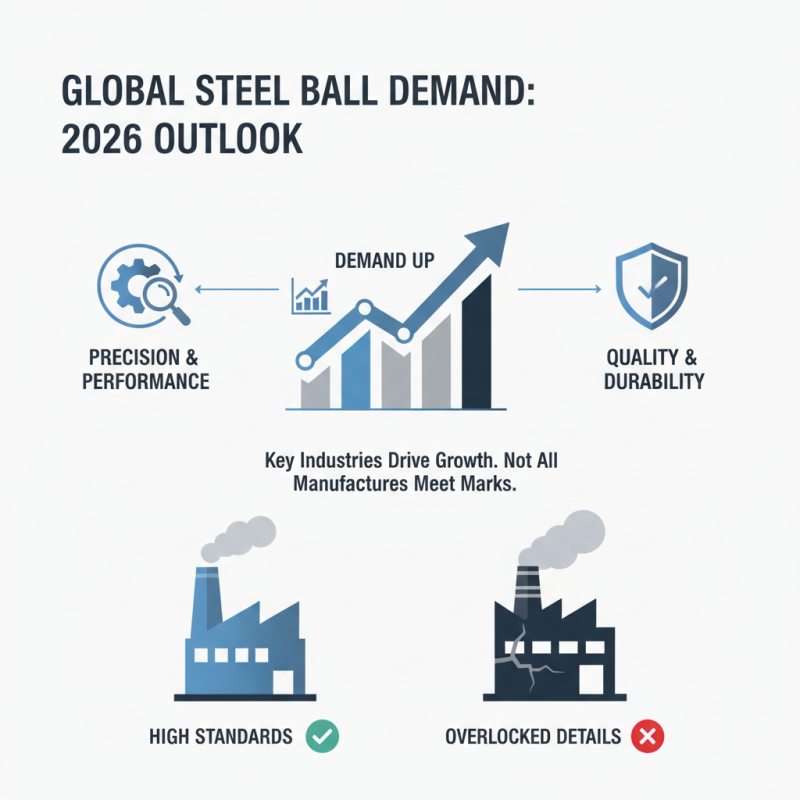

In 2026, the demand for steel balls continues to rise. Precision and performance are key factors in various industries. Many manufacturers strive to meet these needs. Their focus is on quality and durability. However, not all manufacturers uphold high standards. Some may overlook essential details in production.

The leading players in this field invest heavily in research. They explore new materials and methods. Innovations are crucial to maintaining competitive edges. Yet, even top manufacturers face challenges. Production inconsistencies can lead to customer dissatisfaction. This flaw often requires a reevaluation of quality control practices.

Understanding customer needs remains vital. Some manufacturers excel in producing specific sizes. Others focus on custom solutions for unique applications. Despite their efforts, occasional misalignments occur. Companies must adapt continuously to changing market demands. The pursuit of excellence is ongoing, with room for improvement in every step.

Steel balls play a crucial role in various industries. They are essential in applications like automotive, aerospace, and manufacturing. In the automotive industry, steel balls are used in bearings and transmission systems. These components ensure smooth operation and enhance performance. According to a recent report, the automotive sector accounted for over 40% of the global steel ball market in 2023. This indicates the high demand for precision-engineered products.

In the aerospace sector, the demand for steel balls also continues to rise. They are vital in actuators and control systems. These applications require reliable performance under extreme conditions. A study showed that the aerospace industry is expected to grow by 5% annually, thus increasing the need for high-quality steel balls. However, ensuring consistency in quality remains a challenge that needs addressing.

Moreover, steel balls are widely used in manufacturing processes. Industries rely on them for machinery and conveyor systems. The precision of steel balls can significantly affect production efficiency. A report highlighted that improper quality control could lead to machinery failures, emphasizing the need for better standards. Addressing these issues can lead to improved safety and performance across sectors.

In 2026, the demand for high-quality steel balls remains strong across various industries. A comparative analysis highlights the differences in materials and manufacturing processes used by different models. Recent industry reports indicate that precision steel balls with a diameter tolerance of less than ±0.001 mm are preferred for applications in automotive and aerospace sectors. These specifications ensure optimal performance, yet achieving such precision can be challenging, leading to occasional production inconsistencies.

Moreover, performance metrics show that heat treatment plays a crucial role. Steel balls subjected to controlled heat treatments often exhibit superior fatigue resistance. A study found that models with a hardness rating above 60 HRC experience fewer failures under heavy loads. Still, there are instances where even well-manufactured steel balls can falter in harsh conditions. This unpredictability raises questions about quality assurance and testing protocols across the industry.

Another aspect to consider is the environmental impact of steel ball production. Reports indicate that approximately 40% of manufacturers are adopting sustainable practices. However, many still rely on traditional methods, which may generate excess waste and emissions. This highlights an area needing improvement. Balancing precision, performance, and sustainability will be critical as the industry moves forward.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.