Choosing the right metal balls for various engineering projects and applications is crucial to achieving optimal performance and durability. With applications spanning from automotive to aerospace, the demand for high-quality metal balls has seen significant growth in recent years. According to a report from the Global Metal Balls Market Analysis 2022, the market is expected to grow at a CAGR of 5.2% from 2023 to 2030, driven by innovations in materials and manufacturing technologies. This underscores the necessity for industries to select metal balls that meet specific criteria such as material composition, size, and precision.

Expert insights emphasize the importance of careful selection. Dr. James Harrington, a leading authority in mechanical engineering, stated, "The choice of metal balls can significantly influence the effectiveness of machinery and overall project success." His perspective highlights that understanding the various applications—ranging from bearings to precision instruments—can guide professionals in making informed choices. As the industry evolves, staying abreast of the latest trends and developments will empower engineers and designers to enhance their projects through informed decisions regarding metal balls.

When selecting the right metal balls for your projects and applications, it’s essential to understand the various types available in the market. Metal balls come in different materials, each serving unique purposes. Common materials include stainless steel, brass, aluminum, and carbon steel. Stainless steel balls, for instance, are known for their corrosion resistance, making them ideal for applications in humid or chemical-rich environments. Brass balls, on the other hand, offer excellent conductivity and are often used in electrical components.

Tips for selecting the right metal balls: First, consider the environmental factors where the balls will be used. If they need to withstand moisture or harsh chemicals, opt for stainless steel. Also, think about the required weight and density—heavier balls may be preferred for certain mechanical applications, while lighter balls could be better for precision tasks.

Another aspect to consider is the surface finish of the metal balls. Depending on your application, you may need a smooth finish for optimal performance or a textured surface for better grip. Always ensure that you acquire balls that meet the required specifications of your project, as this can significantly impact the efficiency and longevity of your work.

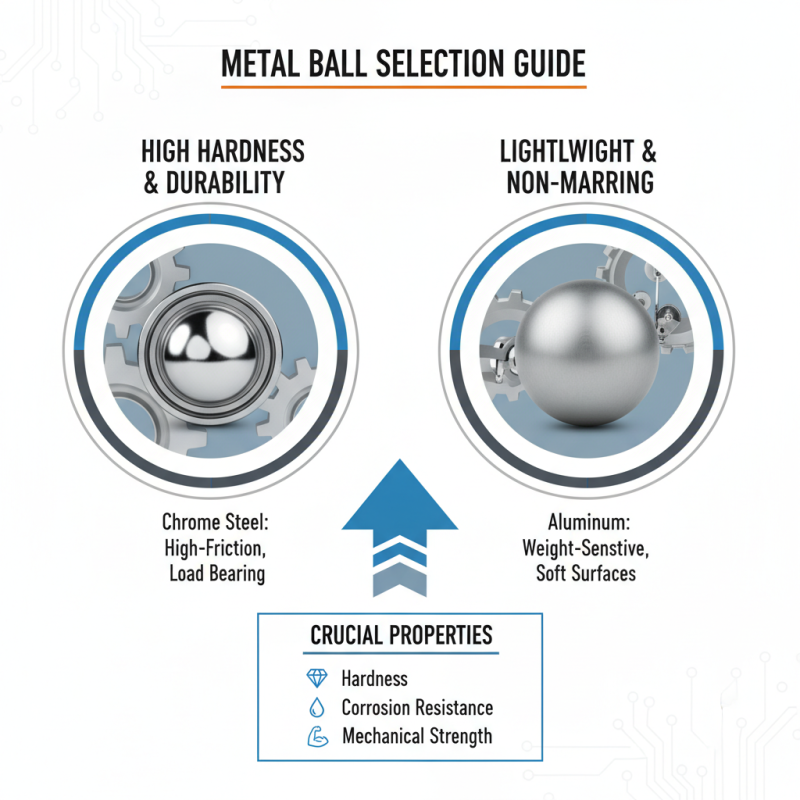

When selecting metal balls for specific applications, the evaluation of material properties is crucial. Different projects require various characteristics from metal balls, such as hardness, corrosion resistance, and mechanical strength. For instance, if the application involves high friction environments, choosing a material with a higher hardness, like chrome steel, can enhance durability and performance. On the other hand, softer materials like aluminum may be suitable for applications where weight and non-marring surfaces are prioritized.

Corrosion resistance also plays a significant role in material selection. For projects exposed to moisture or harsh chemicals, stainless steel or specialized alloys may be the best choice due to their superior resistance to rust and degradation. Additionally, the ball's finish can affect its performance; a smooth finish may reduce friction, while a textured surface may enhance grip in specific applications. Evaluating these properties in relation to the environmental conditions and performance requirements ensures that the right metal balls are chosen to achieve optimal results in any given project.

When selecting the right metal balls for your projects, the first consideration should be the size and weight requirements. These factors significantly influence the balls' functionality in their intended application, whether it’s for bearings, counterweights, or decorative purposes. To determine the appropriate dimensions, it’s crucial to assess the space in which the metal balls will be used. Understanding the clearances and dimensions of adjacent components will help ensure a perfect fit.

Tips: When measuring the required size, always use precise tools to avoid discrepancies. If the project allows for it, consider experimenting with a few different sizes before finalizing your choice. Weight is another critical element; it affects performance and can influence the dynamics of movement in applications. Analyzing the force requirements and how the balls will interact with other elements in the system will guide your decision-making process.

Additionally, consider the material density and its effect on weight. Metal balls come in various materials, each offering different strengths and weights based on their density. For instance, stainless steel is heavier than aluminum, which might be a consideration for projects where weight is a critical factor. By taking accurate measurements and understanding the implications of size and weight, you can make an informed choice that enhances the performance of your project.

| Material | Diameter (mm) | Weight (g) | Hardness (HRC) | Applications |

|---|---|---|---|---|

| Steel | 10 | 8.0 | 40 | Ball bearings |

| Stainless Steel | 12 | 13.0 | 30 | Food processing |

| Aluminum | 8 | 5.0 | 15 | Low friction applications |

| Plastic | 15 | 10.0 | N/A | Toys, decorative use |

| Ceramic | 20 | 25.0 | 50 | Industrial equipment |

When selecting metal balls for various projects, understanding cost considerations and budget constraints is critical. According to a recent industry report by Metal Research Associates, the price of metal balls can vary significantly depending on the material type, production method, and size. For instance, stainless steel balls are often favored for their durability and resistance to corrosion, but they can be more expensive compared to carbon steel alternatives. The report highlights that while stainless steel can cost anywhere from $2 to $5 per unit, carbon steel typically ranges from $0.50 to $1.50 per unit, making it essential for project managers to evaluate their specific needs against their budget limitations.

Furthermore, the production process also impacts pricing. Precision-manufactured metal balls, which are essential for high-performance applications like bearings and aerospace components, often come at a premium. Statistics indicate that precision balls can increase costs by up to 30% compared to standard-grade balls. When budgeting, it’s crucial to factor in not just the upfront costs but also the long-term implications of material choices. Investing in higher-quality metal balls can yield better performance and durability, potentially reducing maintenance and replacement expenditures over time. Thus, a thorough cost analysis, including initial investment and lifecycle expenses, is vital for making informed decisions in selecting the right metal balls for any application.

When selecting metal balls for your projects, it's crucial to find reliable suppliers and manufacturers to ensure product quality and consistency. Start by evaluating potential suppliers based on their reputation in the industry. Look for companies with a proven track record of delivering high-quality metal balls, as well as positive customer feedback and testimonials. Engaging with online forums and industry associations can also provide insights into reputable manufacturers.

Once you've identified a few candidates, inquire about their production processes and quality control measures. A reliable supplier should offer transparent information regarding their manufacturing techniques, material sourcing, and testing protocols. Request samples to assess the quality firsthand, and check if they adhere to industry standards regarding specifications and tolerances. Establishing a good relationship with suppliers who prioritize customer service and communication will enhance the overall purchasing experience and ensure a successful outcome for your projects.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.