When embarking on a project that involves stainless steel, understanding the various stainless steel grades is crucial. According to industry expert Dr. Emily Chen, “Choosing the right stainless steel grade can significantly affect both durability and appearance.” With numerous grades available, each with unique properties, making the right choice can feel overwhelming.

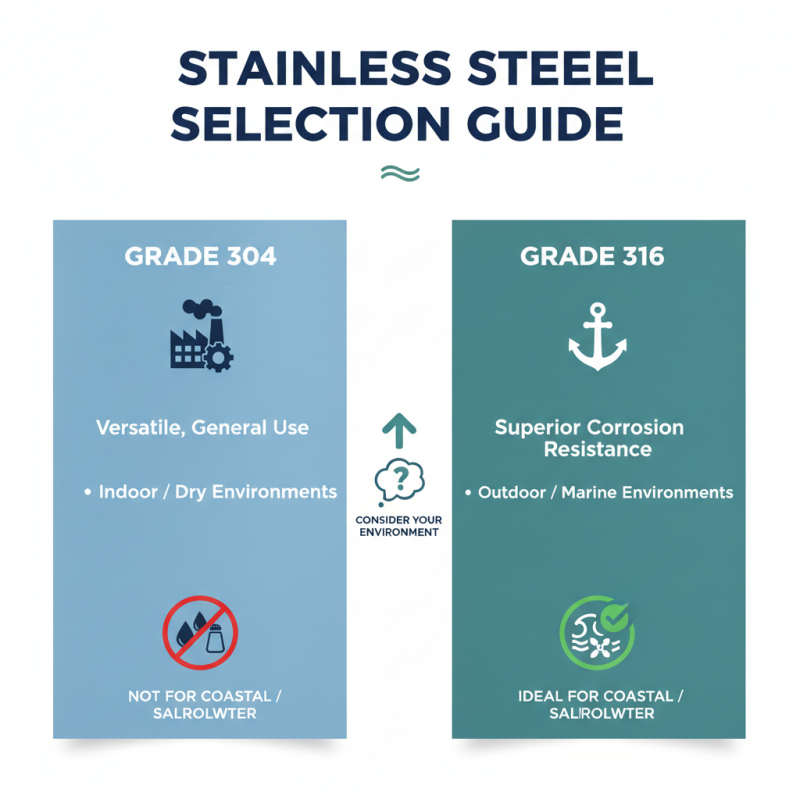

Different projects require different properties. For example, 304 grade is excellent for most indoor applications, while 316 grade offers better corrosion resistance for harsh environments. The choices seem endless. Understanding these differences can lead to mistakes if you overlook specific needs. Sometimes, even experienced professionals second-guess their choices.

The nuances of stainless steel grades directly impact your project's success. Inadequate knowledge can result in unforeseen issues. It’s not just about picking a grade; it’s about knowing how it aligns with your project’s goals and challenges. Whether you’re working on a kitchen renovation or an industrial construction, every detail counts.

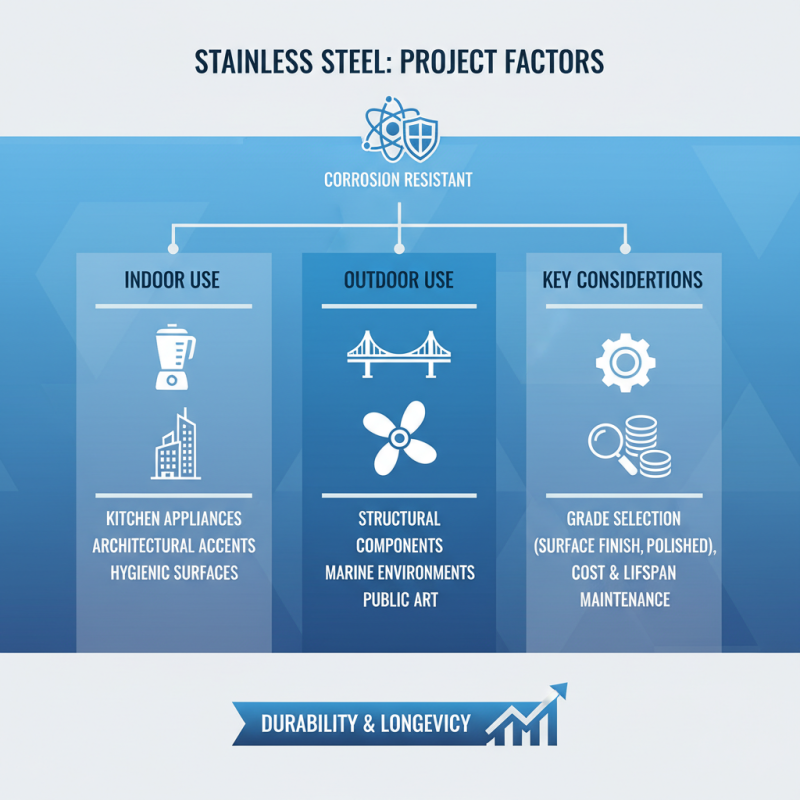

Stainless steel is a material that stands out in many projects. Its resistance to corrosion makes it ideal for both indoor and outdoor applications. When you think of stainless steel, imagine kitchen appliances or sleek architecture. These items rely on this material's durability. But what factors should you consider for your next project?

Different grades of stainless steel serve various purposes. For instance, 304 is often used in kitchens for its excellent formability and corrosion resistance. Meanwhile, 316 stainless steel offers higher durability in marine environments. Choosing the right grade can be challenging. A small oversight can lead to costly errors later on. You may need to reflect on the specific conditions your project could face.

Another critical factor is the maintenance of stainless steel. While it resists rust, it can still develop spots over time. Regular cleaning will help retain its luster. Ignoring this can lead to unsightly surfaces. Think about how often you want to maintain your project. These considerations will guide you. Be prepared to create a plan that fits your needs.

Stainless steel comes in various grades, each designed for specific applications. Understanding these grades is vital for project success. For instance, Grade 304 is commonly used in kitchen equipment. Its resistance to corrosion makes it a popular choice. However, it may not withstand saltwater environments well.

Grade 316 offers better durability. This type contains molybdenum, enhancing its resistance to rust. It’s ideal for marine applications or chemical processing. These characteristics make it a standard in harsh environments. But it can be more expensive than other grades. Consider your budget when selecting.

When working with stainless steel, consider your project's specific needs. Assess the environment where the material will be used. Corrosive settings require higher-grade stainless steel. Pay attention to thickness and finish as well. They can impact overall durability. Choosing the right grade is crucial for longevity. But sometimes, trial and error leads to better understanding. Don't hesitate to learn from past decisions.

| Stainless Steel Grade | Common Uses | Corrosion Resistance | Strength |

|---|---|---|---|

| 304 | Kitchen Equipment, Food Processing, Chemical Containers | Good | Moderate |

| 316 | Marine Applications, Chemical Processing, Medical Devices | Excellent | Moderate |

| 430 | Automotive Trim, Kitchen Utensils, Appliances | Fair | Good |

| 201 | Structural Applications, Kitchen Equipment | Moderate | Good |

| Duplex 2205 | Oil and Gas, Chemical Processing | Very Good | High |

When choosing a stainless steel grade for your project, it's crucial to consider the specific application. Different environments require different properties. For instance, 304 stainless steel is versatile but may not perform well in coastal areas due to corrosion. In contrast, 316 steel is more resistant to saltwater.

**Tip:** Always assess the chemical exposure. Certain grades handle acids better than others. For example, 2205 duplex stainless steel offers increased strength and corrosion resistance, making it suitable for harsh environments. The right choice can drastically affect your project's longevity.

Don't overlook small details. Sometimes, the most suitable grade might not be the most popular one. For indoor applications, 430 stainless steel can be adequate, though it lacks the corrosion resistance of higher grades. It's important to weigh the pros and cons carefully. Always ask, is this choice truly the best for my needs?

When selecting stainless steel for your project, understanding the advantages and disadvantages of each grade is crucial. Common grades include 304 and 316. Grade 304 is popular for its corrosion resistance and formability, making it suitable for kitchen appliances. However, it may not perform as well in harsh environments.

Grade 316, on the other hand, offers enhanced resistance to salt and chemicals. This makes it ideal for marine applications but often comes at a higher cost.

For optimal results, here are some essential tips. First, assess the environment where the stainless steel will be used. A coastal setting? Opt for 316. For general use, 304 is often sufficient. Second, consider the aesthetic appeal. Both grades can be polished to a shine, but 304 tends to have a more appealing surface finish.

One common mistake is underestimating the importance of maintenance. Stainless steel still requires cleaning to prevent corrosion and maintain its look. Also, remember that some grades may not be ideal for welding. It's essential to match the grade with the intended use. Gaining a deep understanding of these details can significantly impact your project's success.

When working with stainless steel, specific practices can significantly enhance your project's outcome. Start by selecting the right grade for your needs. Different grades offer varying corrosion resistance and durability. For instance, 304 stainless steel is ideal for environments that are prone to corrosion. However, it might not hold up in extreme conditions as well as 316 grade. Consider the environment where your project will reside. This choice can impact the longevity of your materials.

Cutting stainless steel requires precision. A dull blade can lead to uneven edges and unnecessary waste. Use protective gear to avoid injuries, as metal shavings can be hazardous. Remember to supervise your workspace. Small distractions could lead to costly mistakes. When welding, ensure proper shielding gas is used. Overheating can weaken the metal structure.

Cleaning is another crucial step. Don’t underestimate the importance of removing residues. A clean surface is essential for effective welding and finishing. Regular maintenance post-project will keep your stainless steel looking its best. Pay attention to minor details. These small steps often lead to significant improvements. Consider the overall design and how the steel fits into it. Reflection on these aspects can set your project apart.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.