Choosing steel ball bearings for your projects can be a daunting task. These components are crucial in various applications, from machinery to robotics. Selecting the right type requires careful thought.

Consider the function of the steel ball bearings. What load will they bear? How fast will they spin? These factors shape your decision. Not all bearings are created equal; different materials and designs offer unique benefits.

Often overlooked is the environmental condition. Will they be exposed to moisture or dust? These elements can affect performance and lifespan. It’s essential to think about both quality and cost. Cheaper options may save money upfront but could fail sooner. Reflecting on your project’s needs will guide you.

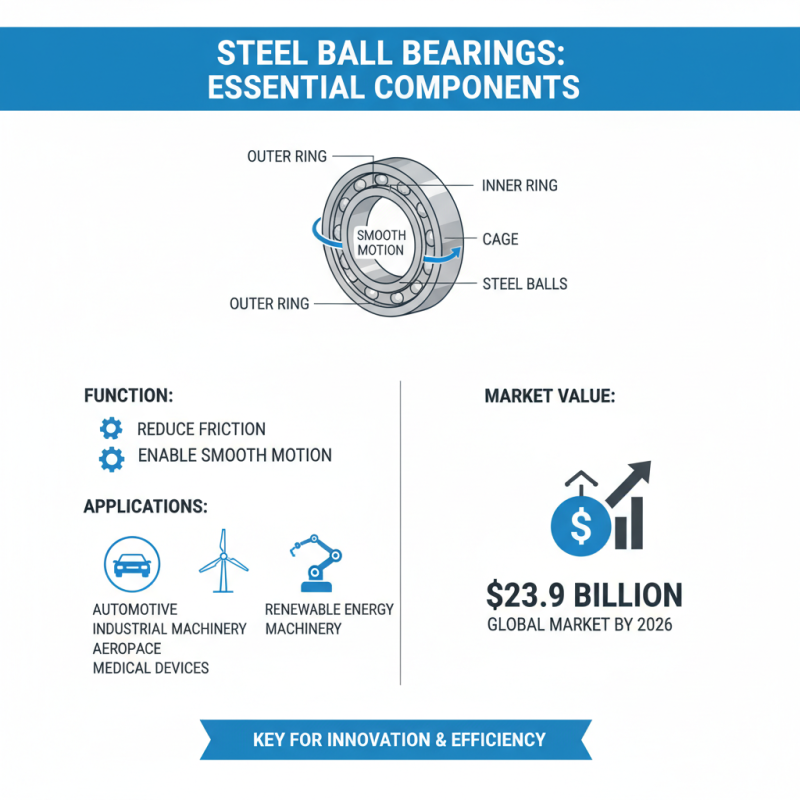

Steel ball bearings are essential components in various machinery and applications, providing smooth motion and reducing friction. Understanding their construction and function is crucial for selecting the right ones for your projects. According to industry reports, the global ball bearing market is projected to reach $23.9 billion by 2026, highlighting their importance across sectors.

When choosing steel ball bearings, consider the load rating. This metric indicates how much weight the bearing can handle safely. Also, examine materials used in manufacturing. High-carbon chromium steel offers excellent wear resistance. However, it may not be suitable for all environments. Corrosion resistance is vital in damp or harsh conditions.

One tip is to assess the operating environment carefully. Humidity, temperature, and exposure to chemicals can impact bearing life. Another crucial aspect is to review the bearing sizes. Standard sizes are widely available but may not always fit specific applications. Custom solutions can be costly, yet they ensure better compatibility and performance. Select bearings that meet precise specifications to avoid future failures. Ultimately, a thoughtful selection process can save both time and resources in your projects.

When selecting steel ball bearings, several key factors come into play. Start by considering the load capacity. Different applications have varying load requirements. Ensure that the bearings can handle the anticipated weight. The material quality is also crucial. High-quality steel can enhance durability. However, not all steel is created equal. Pay attention to the grade and treatment of the steel.

Another factor is the size and type of the bearings. Standard sizes are widely available, yet custom sizes may be necessary for unique projects. Think about the environment as well. Corrosive conditions call for specific coatings or materials, often adding to the cost. Noise and friction levels also matter. Some bearings operate smoother than others. It’s worth evaluating how these factors impact performance.

Lastly, consider the supplier's reputation. Not all suppliers guarantee quality. Research reviews or seek recommendations. Some manufacturers may cut corners, leading to failure. You may find that your initial choice didn’t meet expectations. This situation can be frustrating and costly. Always reassess your options as you learn more about your project's needs.

When selecting steel ball bearings, the material quality is paramount. Steel grade plays a crucial role in determining performance and durability. High-quality steel provides superior strength and resistance to wear. This leads to longer service life in various applications. Choosing the wrong steel grade may result in premature failure. This can impact project efficiency and costs.

Different projects require different steel grades. For instance, high-carbon steel often provides excellent hardness and wear resistance. However, it can be brittle. Lower-grade steels might be more ductile but offer less durability. Each choice comes with trade-offs that can affect your project. Pay attention to these details when making a selection.

In terms of manufacturing processes, even slight imperfections can lead to issues. Small deviations in dimensions can cause misalignment. This leads to increased friction and premature wear. Regular assessments of steel quality help ensure optimal performance. Always consider the environment where the bearings will operate. Corrosive environments may require specialized coatings or stainless steel options. Balancing cost and quality is essential, but don’t forget about long-term implications.

Choosing the right steel ball bearings for your project involves understanding load capacity and size. Different projects require different specifications. Consider the weight your bearings will support. This is crucial. If you underestimate the load, it can lead to failure. A bearing that cannot handle its load will wear out quickly or break.

Next, think about the available space. Measure the area where the bearings will fit. Size matters a lot. Too small, and they may fail under pressure. Too large, and they won’t fit at all. Some people overlook these details. They assume any bearing will work, which often leads to issues.

Always review the load ratings. Each bearing has a limit. Exceeding this can compromise performance. It's essential to match load specifications to your project needs. A little research can save you time and prevent mistakes later on. Don’t rush this decision. Take the time to calculate both load capacity and size for the best results.

| Bearing Type | Load Capacity (kg) | Inner Diameter (mm) | Outer Diameter (mm) | Ball Diameter (mm) | Material |

|---|---|---|---|---|---|

| Deep Groove Ball Bearing | 1500 | 20 | 42 | 10 | Chrome Steel |

| Angular Contact Ball Bearing | 2000 | 30 | 62 | 12 | Stainless Steel |

| Self-Aligning Ball Bearing | 1000 | 25 | 52 | 10 | Carbon Steel |

| Thrust Ball Bearing | 700 | 15 | 40 | 8 | Alloy Steel |

| Miniature Ball Bearing | 300 | 6 | 12 | 3 | Plastic |

Maintaining steel ball bearings is crucial for optimal performance. Regular inspections can identify early signs of wear. Check for rust or noise during operation. Observing these details helps in spotting potential failures before they escalate. Ignoring these symptoms often leads to costly downtime.

Replacement should be considered if bearings show significant wear. Look for pitting or rough surfaces, as these indicate deeper issues. It’s wise to keep a few spare bearings on hand. This simple act can save time during critical projects. Replacing bearings ahead of schedule may seem wasteful, but it prevents unexpected machine failure.

Proper lubrication is another key factor. Keep bearings well-greased to reduce friction. Over-lubrication, however, can trap dirt and debris, leading to failures. Finding the right balance takes practice. Experimenting with different types of lubricants could yield better results. Be prepared to adjust your approach as needed. Reflecting on past experiences can lead to better choices down the line.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.