When it comes to selecting materials for various applications, understanding the properties of different types of stainless steel is crucial. Among the various grades available, 316 stainless steel stands out for its impressive characteristics and versatile applications. This austenitic stainless steel alloy is renowned not only for its resistance to corrosion and rust, but also for its robust mechanical properties, which make it suitable for use in harsh environments. In this context, exploring the unique 316 stainless steel properties can lead to informed decisions in industries ranging from food processing to marine applications.

The significance of 316 stainless steel properties extends beyond mere resistance to corrosion. It offers excellent weldability, durability, and an aesthetic appeal that many other materials cannot match. Additionally, 316 stainless steel retains its strength even at elevated temperatures, making it a preferred choice for high-stress applications. With this comprehensive overview, we aim to highlight the top ten properties of 316 stainless steel that set it apart from other materials and underscore its importance in various industrial sectors. Understanding these properties not only aids in material selection but also enhances the performance, longevity, and safety of end products.

316 stainless steel is an alloy that is well-known for its excellent corrosion resistance and durability, making it a top choice in various industries. The primary composition of 316 stainless steel includes iron, chromium, nickel, and molybdenum. The addition of molybdenum, typically around 2-3%, enhances its resistance to pitting and crevice corrosion in chloride environments, such as those found in marine applications. This unique combination of elements not only improves its strength but also contributes to its aesthetic appeal and workability.

In addition to its corrosion resistance, the composition of 316 stainless steel provides good formability and weldability, which are essential qualities in manufacturing processes. The chromium content, typically around 16-18%, not only contributes to its passive layer that protects against oxidation but also enhances its surface finish. The nickel content, about 10-14%, further improves its ductility and toughness, allowing it to withstand extreme temperatures and stresses. Overall, the intricate balance of these elements makes 316 stainless steel a preferred material in environments where reliability and longevity are critical.

| Property | Description |

|---|---|

| Corrosion Resistance | Highly resistant to corrosion, especially in chloride environments. |

| High Temperature Resistance | Maintains strength and stability at elevated temperatures up to 870°C (1600°F). |

| Strength | Exhibits good tensile strength, making it suitable for various structural applications. |

| Fabricability | Easily fabricated into various shapes and sizes through processes like welding. |

| Ductility | Good ductility allows it to bend without breaking, ideal for forming processes. |

| Aesthetic Appeal | Has a bright, shiny finish that is visually appealing for architectural applications. |

| Non-Magnetic | Generally non-magnetic, making it useful in electronic applications. |

| Thermal Conductivity | Moderate thermal conductivity, which is suitable for heat exchangers. |

| Hygienic | Easily cleaned and sanitized, making it ideal for medical and food applications. |

| Cost | More expensive than 304 stainless steel but offers superior performance in hostile environments. |

316 stainless steel is widely recognized for its exceptional corrosion resistance, particularly in marine environments. This material contains molybdenum, which enhances its resistance to pitting and crevice corrosion in chloride-rich atmospheres typical of coastal and marine settings. The presence of nickel in its composition further contributes to stability, making 316 stainless steel an ideal choice for applications such as shipbuilding, marine hardware, and offshore structures.

In addition to its resistance to saline corrosion, 316 stainless steel maintains its integrity under high temperatures, making it suitable for environments that experience thermal fluctuations. This durability results in lower maintenance costs and prolonged service life for marine applications, where materials are often subjected to harsh conditions. The combination of strength and resistance to chemical attack underscores 316 stainless steel’s prominence in industries that require reliable performance in the face of corrosive agents, ensuring safety and durability in marine infrastructures.

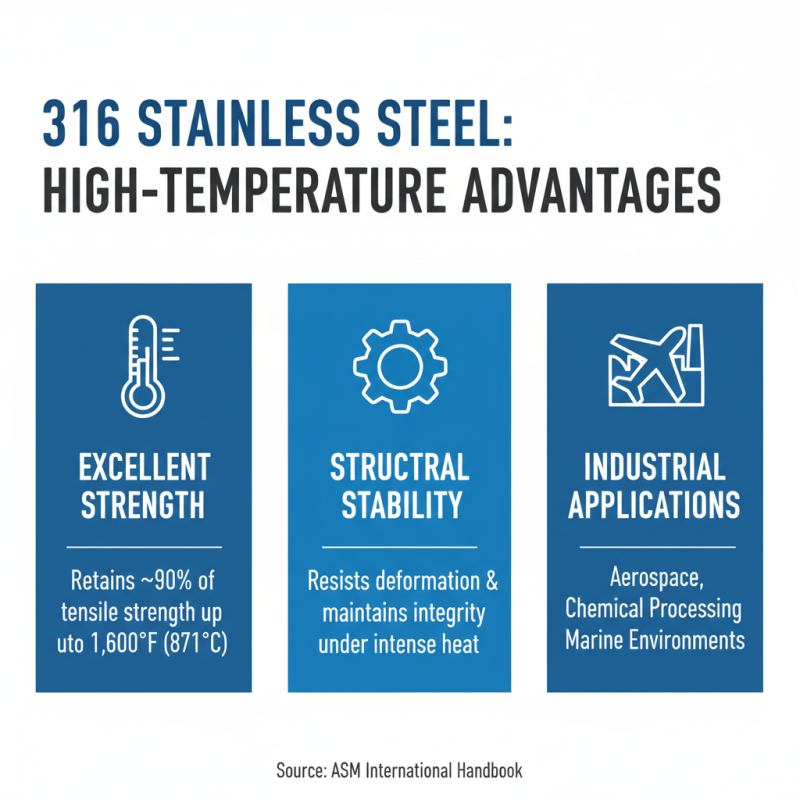

316 stainless steel is renowned for its excellent high-temperature strength and stability, making it a favored choice in various industrial applications. This austenitic stainless steel displays remarkable mechanical properties at elevated temperatures, allowing it to maintain its structural integrity and resist deformation even under intense heat. According to the ASM International Handbook, 316 stainless steel retains approximately 90% of its room temperature tensile strength at temperatures up to 1,600°F (871°C), which is critical for applications in aerospace, chemical processing, and marine environments.

In addition to its strength, 316 stainless steel demonstrates exceptional resistance to oxidation and scaling at high temperatures. Studies published in the Journal of Materials Science indicate that this alloy can withstand temperatures up to 2,000°F (1,093°C) in oxidizing atmospheres without significant degradation, which extends its lifespan in demanding settings. The presence of molybdenum in 316 stainless steel enhances its performance by improving corrosion resistance, especially in harsh environments where high temperatures are combined with corrosive substances. This unique combination of high-temperature stability and durability makes 316 stainless steel an indispensable material in modern engineering and manufacturing processes.

When discussing the mechanical properties of 316 stainless steel, two key characteristics stand out: tensile strength and ductility. 316 stainless steel is known for its high tensile strength, which allows it to withstand substantial loads without deformation. This quality makes it ideal for applications where durability is critical, such as in marine environments and chemical processing. The tensile strength of 316 stainless steel can reach up to 570 MPa, providing robust performance across various conditions.

In addition to its strength, 316 stainless steel boasts impressive ductility. This means the material can be stretched or deformed without breaking, allowing for intricate designs and shapes in manufacturing processes. Ductility is crucial for components that undergo bending or shaping, ensuring they can absorb stress without failure. The combination of high tensile strength and superior ductility is what makes 316 stainless steel a preferred choice in numerous engineering applications.

Tips: When selecting materials for projects, consider not only the tensile strength but also how ductility might affect the performance of the part in real-world conditions. Additionally, ensure that the alloy's resistance to corrosion aligns with the environmental factors it will encounter—this can significantly prolong the life of your projects. Always consult with metallurgical experts when in doubt about material specifications for critical applications.

316 stainless steel is renowned for its exceptional resistance to corrosion and chloride attack, making it a preferred choice across various industries. Its applications can be found in marine environments, chemical processing plants, and food production facilities. In the marine sector, 316 stainless steel is often used for boat fittings, valves, and pumps due to its ability to withstand harsh saltwater conditions. In the chemical industry, it serves well in manufacturing equipment and storage tanks, where exposure to corrosive substances is common.

In addition, 316 stainless steel is widely used in the medical industry, particularly for surgical instruments and implants. Its biocompatibility and ease of sterilization make it an ideal material for these applications. Construction and architecture also benefit from its aesthetic appeal and structural integrity, with 316 stainless steel being utilized in facades, railings, and other architectural elements that require both strength and resistance to harsh environmental conditions.

Tips: When selecting 316 stainless steel for specific applications, consider factors such as temperature extremes, potential exposure to chlorides, and the specific environmental conditions it will face. It’s also advisable to consult with engineers or material specialists to ensure optimal performance and longevity of the components being used. Always maintain proper cleaning and maintenance protocols to maximize the lifespan of 316 stainless steel in any application.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.