In the world of engineering and machinery, the choice of materials significantly influences performance and durability. One area where this is particularly evident is in the use of stainless steel ball bearings, which have become a staple for various applications due to their impressive corrosion resistance and reliability. According to industry expert Dr. Thomas Harrington, a leading figure in bearing technology, “Stainless steel ball bearings not only enhance the lifespan of machinery but also improve overall efficiency, making them an indispensable component in modern design.”

The advantages of stainless steel ball bearings extend beyond their resistance to rust and wear; they are instrumental in maintaining optimal performance under varying operational conditions. This versatility makes them a preferred choice for industries ranging from automotive to aerospace, where precision and longevity are critical. As we delve deeper into the reasons why stainless steel ball bearings are favored for enhanced performance, it's essential to consider both the technical benefits and the long-term cost-effectiveness they bring to engineering applications. By understanding their unique properties, designers and engineers are better equipped to make informed decisions that will significantly impact the efficiency and durability of their projects.

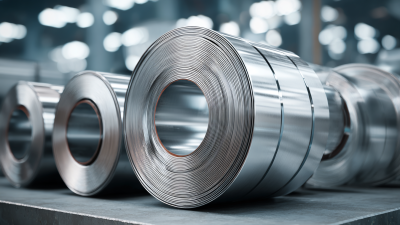

Stainless steel ball bearings are increasingly favored across various industries due to their unmatched performance and durability. These components provide a significant advantage in applications that require high precision and reliability. According to a report by the American Bearing Manufacturers Association, bearings made from stainless steel offer a longer service life, sometimes exceeding that of standard carbon steel bearings by over 40%. This enhancement is primarily attributed to their resistance to corrosion and wear, making them ideal for environments exposed to humidity, chemicals, or extreme temperatures.

In addition to their longevity, stainless steel ball bearings exhibit superior load-carrying capacity and reduced friction compared to alternative materials. A study published in the Journal of Mechanical Engineering highlighted that stainless steel bearings demonstrated up to a 30% reduction in frictional losses, resulting in improved energy efficiency. This feature is crucial in applications such as electric motors and robotics, where minimizing energy consumption while maximizing performance is essential. As industries strive for greater efficiency and sustainability, the demand for stainless steel ball bearings continues to grow, underpinning their role as a cornerstone of modern engineering solutions.

When it comes to selecting bearings for various applications, the choice of material plays a crucial role in determining performance and longevity.

Stainless steel ball bearings stand out when compared to traditional materials like plastic or carbon steel.

While plastic bearings may offer corrosion resistance, they often lack the load-bearing capacity required for high-stress environments.

Meanwhile, carbon steel bearings might excel in strength but can suffer from rust and degradation when exposed to moisture and harsh conditions.

Stainless steel bearings, on the other hand, provide an optimal balance of strength, corrosion resistance, and durability, making them suitable for a wide range of applications.

Tips: When selecting bearings for your application, consider the environment in which they will operate. If exposed to moisture or chemicals, stainless steel ball bearings may be your best option due to their superior resistance to deterioration.

Additionally, always check the load ratings of the bearings to ensure they can withstand the specific pressures of your application.

Furthermore, the smooth surface finish of stainless steel bearings reduces friction, which not only enhances efficiency but also minimizes heat generation.

This quality can significantly extend the lifespan of the bearing, making it a more cost-effective choice over time.

By evaluating the specific needs of your application and considering the environmental factors, stainless steel ball bearings often emerge as the most reliable choice for maintaining optimal performance.

Tips: Regular maintenance and lubrication can also contribute to better performance and longevity of stainless steel ball bearings.

Ensure that you adhere to recommended service intervals to maximize their efficiency and lifespan.

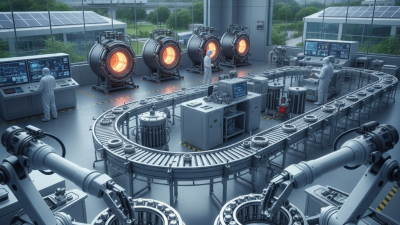

When considering the performance of stainless steel ball bearings, several factors come into play that can significantly influence their functionality and durability. One of the primary factors is the quality of the stainless steel used in their construction. Bearings made from high-grade stainless steel, such as AISI 440C, offer superior corrosion resistance and strength compared to lower grade alloys. This is crucial in preventing wear and tear over time, especially in applications exposed to moisture or harsh environments.

Another critical factor that affects their performance is the precision of the manufacturing process. High-quality ball bearings are produced with tight tolerances and smooth finishes, reducing friction and enhancing operational efficiency. Additionally, factors such as lubrication, load capacity, and operating temperature also play vital roles in determining the overall lifespan and functionality of stainless steel ball bearings. Proper lubrication ensures smooth movement and reduces heat generation, while understanding the load capacities helps in selecting the right bearing for specific applications, thereby preventing premature failure.

When it comes to maintaining stainless steel ball bearings, regular upkeep and attention to detail are crucial for ensuring their longevity and optimal performance. One of the primary maintenance tips is to keep the bearings clean. Dirt and debris can accumulate, leading to wear and corrosion over time. Utilizing a mild detergent and warm water to clean the bearings, followed by thorough drying, is recommended. Additionally, applying a suitable lubricant can significantly reduce friction and improve efficiency, prolonging the life of the bearings.

Another essential aspect of maintenance involves monitoring for signs of wear or damage. Regular inspections will help identify any issues early on, such as pitting or discoloration, that could signal deterioration. If any irregularities are detected, replacing the bearings promptly is vital to prevent further equipment damage. Furthermore, ensuring proper installation to minimize stress on the bearings can enhance their performance, reducing the risk of failure. By adhering to these maintenance practices, users can effectively extend the lifespan of stainless steel bearings, maximizing their return on investment and ensuring continued operational excellence.

The industrial sector is increasingly recognizing the advantages of stainless steel ball bearings, particularly in enhancing performance and ensuring longevity in machinery. Reports indicate that the global stainless steel bearings market is projected to grow at a compound annual growth rate (CAGR) of 5.2% between 2021 and 2028. This trend is largely attributed to their superior resistance to corrosion, wear, and fatigue compared to traditional steel ball bearings. As industries aim for greater efficiency and reduced maintenance costs, the transition towards stainless steel alternatives becomes a strategic decision.

In specific applications, such as food processing and pharmaceuticals, the use of stainless steel ball bearings is almost mandatory due to stringent hygiene standards. Their ability to withstand cleaning agents and high temperatures makes them a preferred choice for manufacturers aiming to comply with safety regulations. Additionally, studies show that the lifespan of stainless steel bearings can be approximately 30% longer than that of their carbon steel counterparts, significantly reducing downtime and replacement costs.

Tips: When selecting stainless steel ball bearings, consider environments where moisture and contaminants are prevalent. Opting for bearings with enhanced sealing options can further extend their service life, providing added protection against external elements. Regular maintenance inspections can also help identify wear early, ensuring optimal performance throughout their operational lifespan.

This chart illustrates the performance comparison between stainless steel and carbon steel ball bearings across several key metrics. The data reflects the advantages of stainless steel ball bearings in terms of corrosion and temperature resistance, leading to enhanced performance and longevity in various industrial applications.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.