In the realm of construction and manufacturing, the choice of materials significantly impacts the quality and durability of the final product. Stainless steel, revered for its strength and resistance to corrosion, is a material of choice for many industries. However, not all stainless steels are created equal; understanding the various stainless steel grades is crucial for selecting the right one for your specific project. As noted by industry expert Dr. Alan Steele, “The selection of the appropriate stainless steel grade can make or break a project in terms of longevity and performance.”

In this article, we will explore the top 10 stainless steel grades that every professional should be familiar with. Each grade boasts unique properties that cater to a wide range of applications, from architectural designs to industrial machinery. By delving into the characteristics and advantages of these grades, we aim to equip you with the knowledge needed to make informed decisions in your projects. Understanding stainless steel grades is not merely a technical necessity; it enhances both efficiency and sustainability in material selection, ultimately leading to the success of your endeavors.

Stainless steel grades play a crucial role in the selection of materials for various projects across industries. Understanding the differences between these grades is essential, as each type offers unique properties that influence their suitability for specific applications. From corrosion resistance to strength and durability, the right grade can significantly impact the performance and longevity of the final product. Different environments, such as marine, chemical, or high-temperature settings, demand careful consideration of the stainless steel grade to ensure optimal results.

The importance of choosing the right stainless steel grade cannot be understated, as it directly affects factors such as maintenance, safety, and cost-effectiveness. For instance, a grade with high corrosion resistance may be ideal for chemical processing environments, while a grade with excellent mechanical properties may be preferred for structural applications. This knowledge empowers engineers and project managers to make informed decisions that enhance the reliability and efficiency of their projects, ultimately leading to better outcomes and reduced risks associated with material failures.

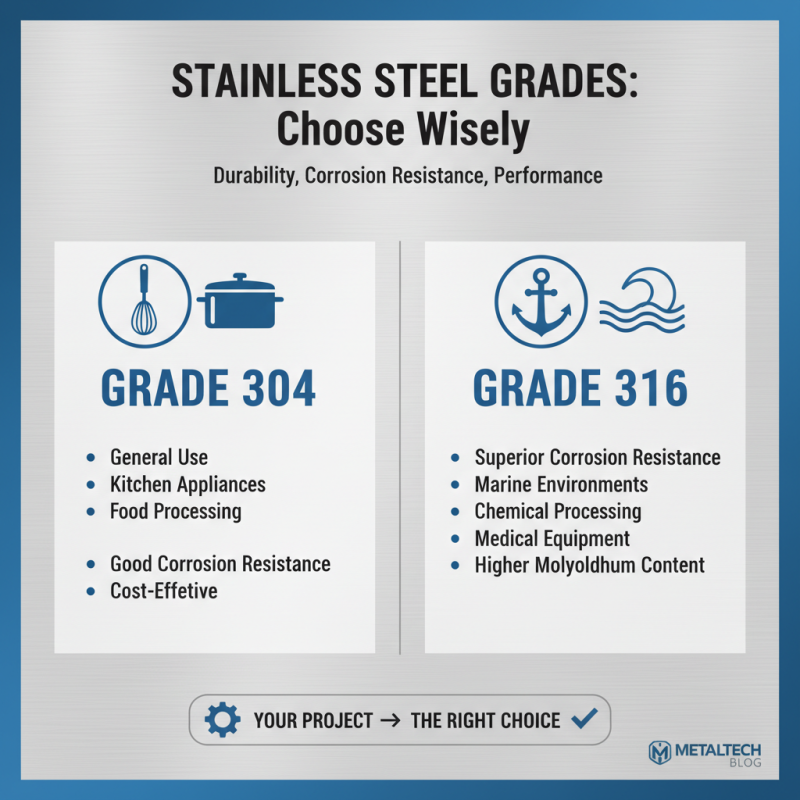

When selecting stainless steel for your projects, understanding the key properties of different grades is essential. These properties can significantly influence the performance, durability, and aesthetic quality of the final product. Corrosion resistance is one of the most crucial characteristics to consider, as it determines how well the stainless steel will withstand environmental factors such as moisture, chemicals, and temperature fluctuations. For instance, grades like 304 and 316 offer robust resistance to rust and corrosion, making them ideal for applications in harsh environments.

Another vital property to consider is tensile strength, which measures the material's ability to withstand pulling forces without breaking. Higher tensile strength grades, such as 440 and 630, are often used in applications that demand high durability and strength, such as in the automotive or aerospace industries. Additionally, factors like ductility and machinability are important for ensuring that the stainless steel can be easily shaped and formed without compromising its integrity. Understanding these properties helps in selecting the right stainless steel grade that meets the specific requirements of your project, ultimately leading to better performance and longevity of the finished product.

Stainless steel is an essential material in various industries due to its durability, resistance to corrosion, and aesthetic appeal. Understanding the features and appropriate applications of different stainless steel grades can significantly impact the success of projects. Among the most commonly used grades, 304 stainless steel stands out for its versatility. Known for its excellent corrosion resistance, it is commonly utilized in kitchen equipment, piping, and food processing. Its ability to maintain hygiene and withstand extreme temperatures makes it a popular choice for both residential and commercial applications.

Another important grade is 316 stainless steel, which offers enhanced corrosion resistance, particularly against chlorides. This makes it an ideal selection for marine environments and chemical processing plants. Additionally, grade 430 is a ferritic stainless steel that provides good corrosion resistance at a lower cost. It is often used in automotive applications and kitchen appliances where aesthetic appeal and resistance to oxidation are necessary but extreme corrosion resistance is not critical. Understanding these features allows for better material selection tailored to meet the specific needs of each project, ensuring longevity and reliability in performance.

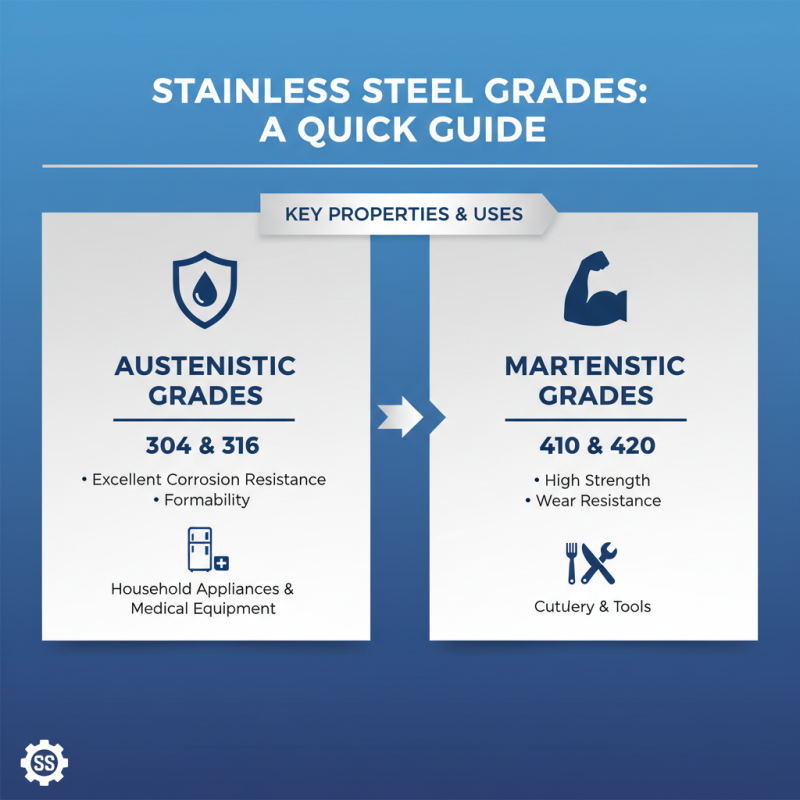

When embarking on projects involving stainless steel, understanding the different grades is crucial for both performance and durability. Each grade of stainless steel offers distinct properties that cater to various applications. For example, austenitic grades, such as 304 and 316, are known for their excellent corrosion resistance and formability, making them ideal for household appliances and medical equipment. Conversely, martensitic grades like 410 and 420 provide higher strength and wear resistance but may have reduced corrosion resistance, making them suitable for cutlery and tools.

Furthermore, duplex stainless steels combine the properties of both austenitic and ferritic grades, offering high strength and enhanced resistance to stress corrosion cracking. This makes duplex grades particularly beneficial for applications in the oil and gas industry. When selecting the appropriate stainless steel grade, factors such as the environment, mechanical properties, and welding considerations should be assessed to ensure optimal performance and longevity of the material in your projects.

Choosing the right stainless steel grade for your project is crucial, as it directly affects the durability, corrosion resistance, and overall performance of the finished product. Stainless steel comes in various grades, each with its unique properties suited for different applications. For example, grades like 304 and 316 are among the most common for general use, with 304 being ideal for kitchen applications and 316 being a superior choice for marine environments due to its enhanced corrosion resistance.

When selecting a stainless steel grade, it's essential to consider factors such as the operating environment, required strength, and potential exposure to chemicals. High-performance grades like 2205 duplex stainless steel offer excellent strength and corrosion resistance in harsh conditions, making them suitable for oil and gas applications. Conversely, austenitic grades such as 310 provide exceptional heat resistance, making them ideal for high-temperature environments. By understanding the specific requirements of your project, you can make an informed decision that ensures longevity and effectiveness in your stainless steel applications.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.