As we look towards 2025, the world of manufacturing and engineering is on the brink of exciting advancements, particularly in the realm of precision components. Among the unsung heroes of mechanical systems, steel ball bearings play a critical role in ensuring optimal performance and efficiency. These small yet powerful elements are essential in reducing friction, enhancing durability, and improving the overall functionality of machinery across various industries. With technology evolving rapidly, it is crucial to stay informed about the best options available on the market.

In this article, we will explore the top 10 steel ball bearings to watch in 2025. Each selection has been carefully evaluated for its design, material composition, and performance capabilities, ensuring they meet the increasing demands of modern applications. From automotive and aerospace to industrial machinery, the right steel ball bearings can significantly impact operational efficiency and reliability. Join us as we delve into the features and benefits of these standout products, equipping you with the knowledge to make informed choices for optimal performance in your projects.

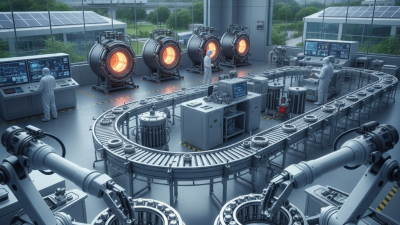

As we look forward to 2025, several innovations in steel ball bearings promise to enhance performance and efficiency across various industries. One key trend is the integration of advanced materials, such as hybrid bearings that combine steel with ceramic elements. These hybrid designs not only reduce weight but also improve resistance to wear and corrosion, leading to longer service lives and decreased maintenance costs. Additionally, the use of nanotechnology in surface coatings is gaining traction, which can significantly lower friction levels and enhance operational capabilities under extreme conditions.

Another crucial trend to watch is the increasing incorporation of smart technologies within bearing systems. Sensors embedded in steel ball bearings can provide real-time data on temperature, load, and operational health, enabling predictive maintenance and reducing downtime. This shift toward IoT-enabled bearings allows manufacturers to optimize performance and extend the life of machinery. The focus on sustainability is also noteworthy, with companies exploring eco-friendly manufacturing processes and recyclable materials to meet both regulatory demands and consumer expectations. These innovations not only promise to improve performance but also pave the way for a more sustainable industrial future.

| Bearing Type | Load Capacity (N) | Diameter (mm) | Material | Innovative Features | Expected Cost (USD) |

|---|---|---|---|---|---|

| Deep Groove Ball Bearing | 4000 | 20 | Stainless Steel | Low friction design | 25 |

| Angular Contact Ball Bearing | 5000 | 30 | High Carbon Steel | Dual-row configuration | 35 |

| Self-Aligning Ball Bearing | 3000 | 25 | Ceramic | Reduced wear and vibration | 40 |

| Thrust Ball Bearing | 7000 | 15 | Chrome Steel | Load stability | 30 |

| Spherical Roller Bearing | 6500 | 35 | Alloy Steel | Higher axial loading | 50 |

| Precision Ball Bearing | 8000 | 10 | Hybrid Ceramic | High speed capability | 70 |

| Magnetic Ball Bearing | 5000 | 20 | Magnetic Steel | Frictionless operation | 60 |

| Miniature Ball Bearing | 2000 | 8 | Stainless Steel | Compact design | 20 |

| Flanged Ball Bearing | 3500 | 25 | Chrome Steel | Easy installation | 45 |

| Cylindrical Roller Bearing | 9000 | 40 | Carbon Steel | Heavy load handling | 80 |

When selecting high-performance steel ball bearings, a focus on reduced friction and wear is critical for ensuring longevity and efficiency in various applications. The right bearings can significantly enhance the performance of machinery, leading to smoother operations and lower maintenance costs. In 2025, as technology advances, several standout options will likely be at the forefront due to their innovative design and materials that promise to mitigate friction effectively.

When choosing steel ball bearings, consider the lubrication type. Utilizing high-quality lubricants can further reduce friction and wear, ensuring that your bearings perform optimally even under extreme conditions. Additionally, look for bearings with advanced surface treatments that enhance durability and resistance to abrasive wear. These features will not only prolong the life of the bearings but also improve reliability in high-speed applications.

Another important aspect is the bearing's load capacity and speed rating. Ensure that the bearings you select align with the specific demands of your application. By paying attention to these details and selecting high-performance options, you can optimize the efficiency and lifespan of the bearings in your systems.

As we move toward 2025, the landscape of steel ball bearings is set to undergo significant transformations driven by advanced manufacturing techniques. Innovations such as additive manufacturing and precision machining are enhancing not only the efficiency of production but also the overall quality of ball bearings. According to a recent report by MarketsandMarkets, the global ball bearing market is expected to reach USD 21.4 billion by 2025, highlighting the growing demand for high-performance bearings across various industries.

Advanced manufacturing techniques contribute to improved material properties and precision tolerances, which are critical for optimal bearing performance. For instance, the use of high-strength alloys and surface hardening technologies can increase the load capacity and lifespan of bearings. A study published by the American Society of Mechanical Engineers (ASME) indicates that bearings produced using laser additive manufacturing exhibit a 30% improvement in fatigue resistance compared to traditional methods. This leap in performance is essential for applications ranging from automotive to aerospace, where reliability and efficiency are paramount.

Furthermore, the integration of smart manufacturing technologies, such as IoT and AI, is expected to play a pivotal role in quality control processes. Real-time monitoring and predictive maintenance can significantly reduce failure rates and enhance the operational efficiency of bearing systems. With the ongoing advancements in technology and manufacturing processes, the steel ball bearing market is poised for substantial growth and innovation in the coming years.

The global steel ball bearings market is poised for significant growth through 2025, with projections indicating an increase from $7.26 billion in 2025 to $12.15 billion by 2032, achieving a compound annual growth rate (CAGR) of 7.6%. This robust growth is expected to be driven by advancements in manufacturing technologies and the rising demand in various industries, particularly automotive and aerospace, where reliability and efficiency are paramount.

As the market evolves, companies must focus on optimizing their product offerings.

**Tips:** Invest in research and development to stay at the forefront of innovation. Implement strategies for quality control to ensure product reliability, which is critical for customer satisfaction and brand trust.

Moreover, the mixed ceramic ball bearing segment is also noteworthy, with market estimates projecting a rise from $3.36 billion in 2024 to $5.2 billion by 2033, reflecting a CAGR of 4.2%. North America is expected to lead this market, highlighting the region's importance in both the production and application of advanced bearing technologies.

**Tips:** Monitor emerging trends and technologies in bearing manufacturing, as adapting to these changes can yield a competitive edge. Engage with end-users to understand their evolving needs better and tailor solutions that enhance performance and efficiency.

As we look ahead to 2025, sustainability in steel ball bearings is becoming a crucial consideration for manufacturers and consumers alike. The shift towards eco-friendly materials not only benefits the environment but also enhances the performance and longevity of these essential components. Innovations in recycling methods and the use of sustainable materials like bioplastics and low-carbon steel are gaining traction, resulting in production processes that minimize waste and energy consumption.

Tips: When selecting steel ball bearings, consider those that utilize recycled materials or are produced through energy-efficient processes. This not only supports environmental initiatives but can also lead to better performance in the long run.

Manufacturers are increasingly adopting green manufacturing practices, implementing water conservation methods and reducing carbon footprints. This trend reflects a growing awareness of corporate responsibility and consumer demand for sustainable products. As companies strive to balance performance with eco-friendliness, the development of advanced coatings and lubricants that are biodegradable is also on the rise.

Tips: Look for certifications or labels indicating eco-friendly production practices when purchasing ball bearings. This not only ensures high quality but supports a broader commitment to sustainability in the industry.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.