Unlocking the versatility of 304 stainless steel begins with a deep understanding of its unique properties, which make it an indispensable material across various industries. According to a recent report by Grand View Research, the global stainless steel market is projected to reach USD 156.6 billion by 2025, with a substantial demand driven by the exceptional characteristics of 304 stainless steel properties. This austenitic grade is renowned for its outstanding corrosion resistance, high tensile strength, and excellent formability, making it ideal for applications ranging from kitchen utensils to medical equipment. Furthermore, its ability to withstand extreme temperatures and maintain structural integrity under stress positions 304 stainless steel as a preferred choice in the construction, automotive, and manufacturing sectors. As we explore the top features of this remarkable alloy, the insights gained can help maximize its potential in innovative applications and designs.

304 stainless steel is renowned for its outstanding corrosion resistance, making it a popular choice in various industrial environments. According to the Corrosion Engineering Association, this alloy's austenitic structure provides enhanced resistance against pitting and crevice corrosion, particularly in chlorine-rich environments. In fact, a study published in the Journal of Materials Science indicated that 304 stainless steel maintains its integrity when exposed to a corrosive atmosphere containing up to 3% chloride ions for extended periods.

304 stainless steel is renowned for its outstanding corrosion resistance, making it a popular choice in various industrial environments. According to the Corrosion Engineering Association, this alloy's austenitic structure provides enhanced resistance against pitting and crevice corrosion, particularly in chlorine-rich environments. In fact, a study published in the Journal of Materials Science indicated that 304 stainless steel maintains its integrity when exposed to a corrosive atmosphere containing up to 3% chloride ions for extended periods.

Furthermore, 304 stainless steel exhibits excellent performance in both acidic and alkaline conditions. The National Association of Corrosion Engineers (NACE) has reported that 304 stainless steel remains largely unaffected when exposed to environments containing sulfuric and hydrochloric acids at low concentrations. This versatility is crucial in the food processing and chemical industries, where sanitation and resistance to aggressive cleaning agents are paramount. As a result, 304 stainless steel is often the material of choice for equipment such as storage tanks, piping, and valves. Its ability to withstand various corrosive situations underscores its value across multiple applications, ensuring durability and longevity.

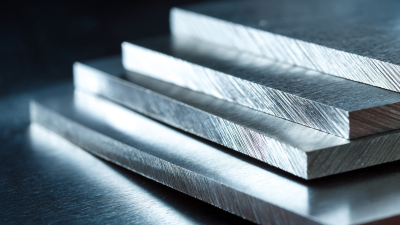

The aesthetic appeal of 304 stainless steel lies not only in its polished surface but also in its versatility across various design contexts. Its sleek, modern finish complements a wide range of styles, from industrial chic to minimalist aesthetics. Designers often choose 304 stainless steel for countertops, backsplashes, and fixtures, as it adds a contemporary touch while maintaining functionality. The material's ability to resist corrosion and staining ensures that it retains its visual allure over time, making it a favorite choice in both residential and commercial spaces.

In contemporary design, 304 stainless steel serves as a canvas for creativity. Its reflective surface can enhance natural light, creating an illusion of spaciousness within interiors. Additionally, when combined with wood, glass, or stone, it articulates a harmonious balance that enhances overall design elements. The ability of 304 stainless steel to adapt to various textures and colors allows designers to craft unique statements that resonate with users, making it an essential material for those looking to achieve a modern aesthetic without compromising on durability.

304 stainless steel is renowned for its versatility and robustness, making it a preferred material across various industries. With its impressive thermal conductivity, 304 stainless steel plays a significant role in applications ranging from cookware to industrial machinery. In 2023, the global stainless steel market was valued at an astonishing $206.91 billion, with projections indicating a growth to $320.37 billion by 2032. This surge is particularly driven by increasing demands in construction, automotive, energy, and manufacturing sectors.

Recent studies highlight that the market for stainless steel bars and shapes is expected to exceed $23 billion in 2024, with a compound annual growth rate of 4.5% from 2025 to 2034. This growth echoes the wide-ranging applications of 304 stainless steel, exemplified by its use in innovative structures like the “stainless steel pool” in Chongqing's Wuling Mountain Forest Park. The choice of 304 stainless steel, with its remarkable durability and aesthetic appeal, underscores its importance in modern engineering solutions. Additionally, the global stainless steel plate market is anticipated to rise from $112.43 billion in 2023 to $167.48 billion by 2030, reflecting an annual growth rate of 5.9%.

304 stainless steel is renowned not only for its durability but also for its exceptional ease of fabrication and welding. According to the "Stainless Steel Fabrication Market Outlook 2023," over 65% of fabricators prefer 304 stainless steel due to its favorable mechanical properties, which include high tensile strength and excellent corrosion resistance. This alloy exhibits a good balance of strength, ductility, and formability, making it an ideal choice for various applications, from kitchen equipment to architectural structures.

The welding characteristics of 304 stainless steel further contribute to its popularity in the industry. The material can be readily welded using traditional methods such as MIG, TIG, and resistance welding. A report by the American Welding Society highlights that 304 stainless steel maintains its integrity during the welding process, with minimal risk of cracking or distortion. Its low carbon variant, 304L, is especially beneficial for welded structures, minimizing the risk of carbide precipitation. This combination of properties makes 304 an essential material in sectors like automotive, food processing, and pharmaceuticals, where robust and clean fabrication is critical.

304 stainless steel is celebrated not only for its impressive mechanical properties but also for its cost-effectiveness and longevity in manufacturing applications. This versatile alloy contains 18% chromium and 8% nickel, which enhance its resistance to corrosion and oxidation. These features make it ideal for environments that involve exposure to moisture and various chemicals, significantly reducing the need for replacements or repairs over time. As a result, companies can save on lifecycle costs, making 304 stainless steel an economical choice for both large-scale and small manufacturing processes.

In addition to its durability, the manufacturing efficiency of 304 stainless steel also contributes to its cost-effectiveness. The material is known for its ease of fabrication, allowing manufacturers to shape, cut, and weld it with minimal effort. This capability not only accelerates production timelines but also lowers labor costs. Furthermore, the long-lasting nature of 304 stainless steel means that products made from this material maintain their integrity and aesthetic appeal over extended periods, thereby ensuring customer satisfaction and reducing overall expenditures on maintenance and replacement.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.